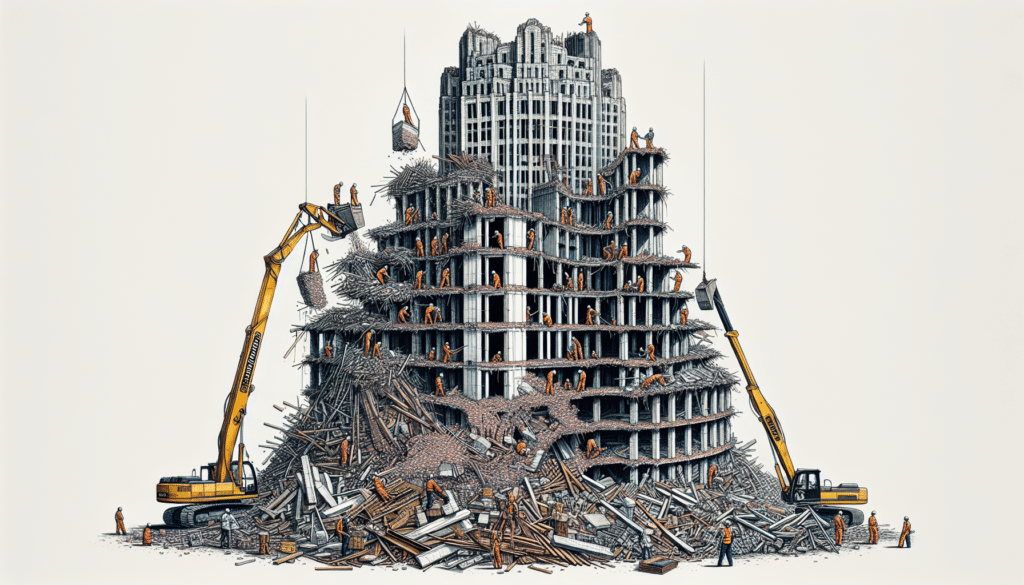

Deconstruction of buildings is a sustainable method of dismantling structures to salvage and reuse materials. Unlike demolition, which creates significant waste, deconstruction aims to minimize environmental impact by carefully removing components for reuse. In this article, we will discuss the benefits of deconstruction, the best practices for carrying it out, and how it differs from traditional demolition.

Key Takeaways

- Deconstruction offers a sustainable alternative to traditional demolition. It allows the reuse and repurposing of building materials, thereby reducing construction waste and environmental impact.

- Successful deconstruction projects rely on precise planning, certified contractors, and effective inventory management, ensuring maximized material recovery and compliance with safety regulations.

- The transition to deconstruction is supported by setting clear goals, establishing local markets for salvaged materials, and implementing favorable policies and incentives to encourage its adoption.

Introduction

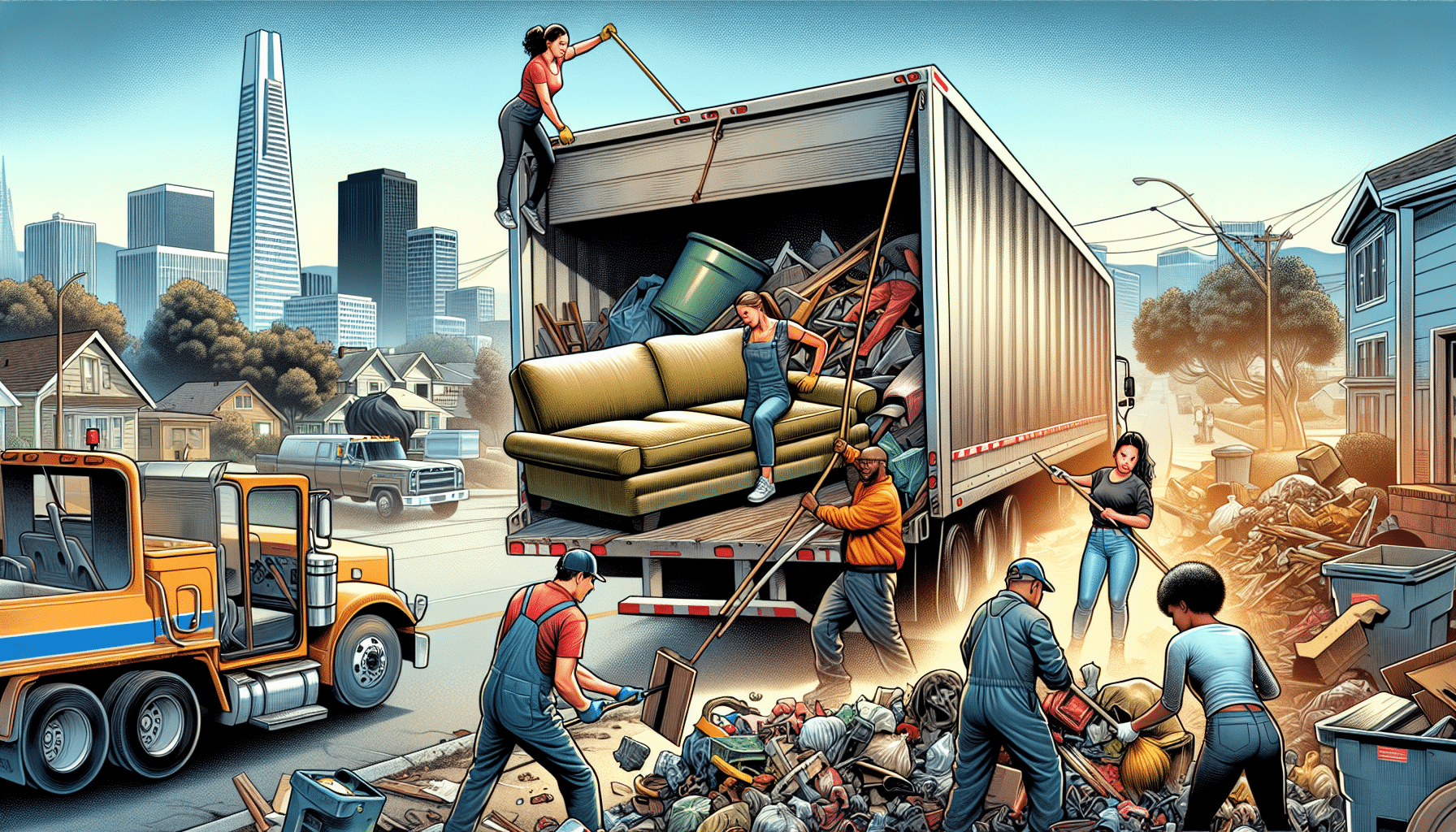

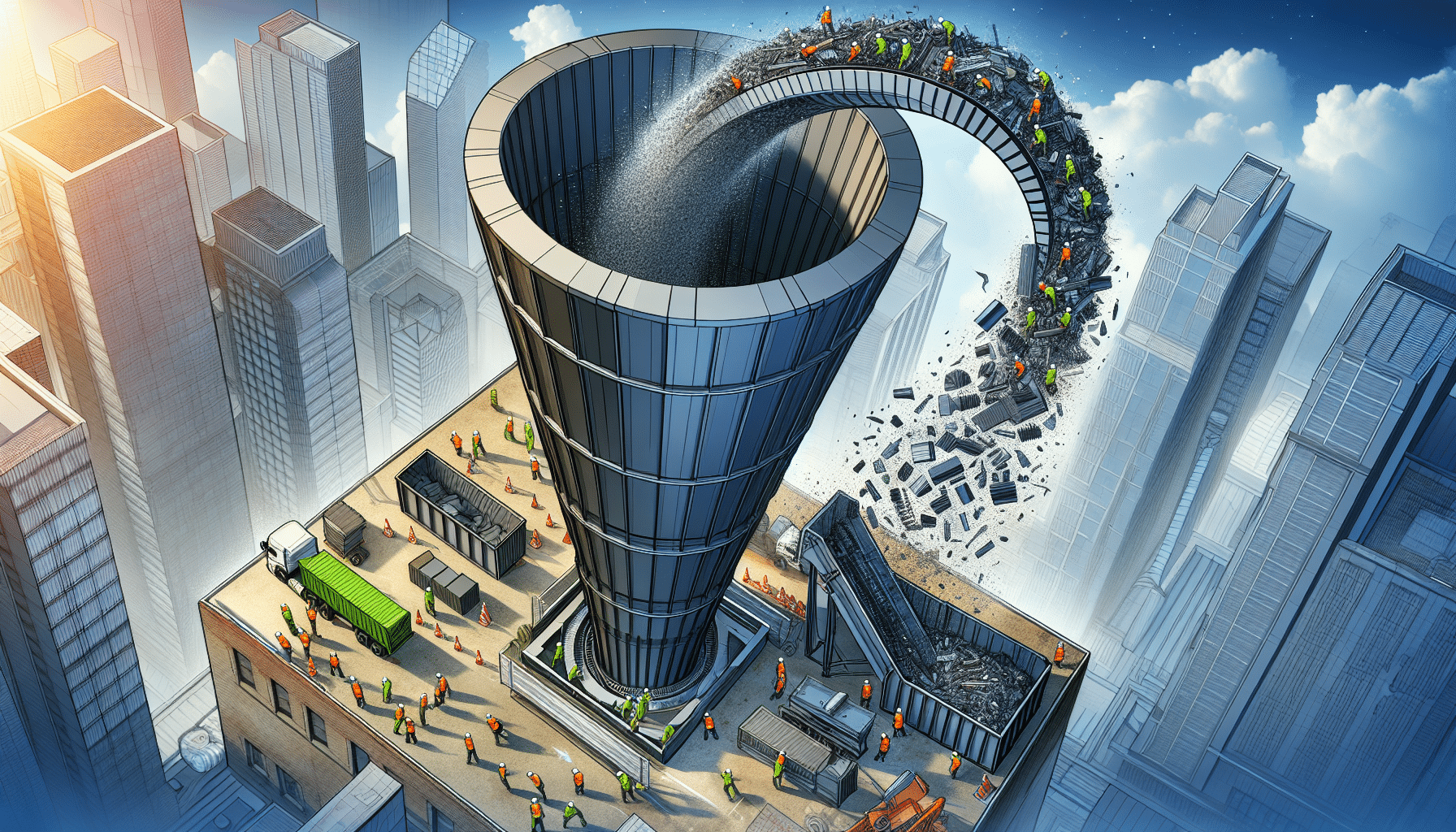

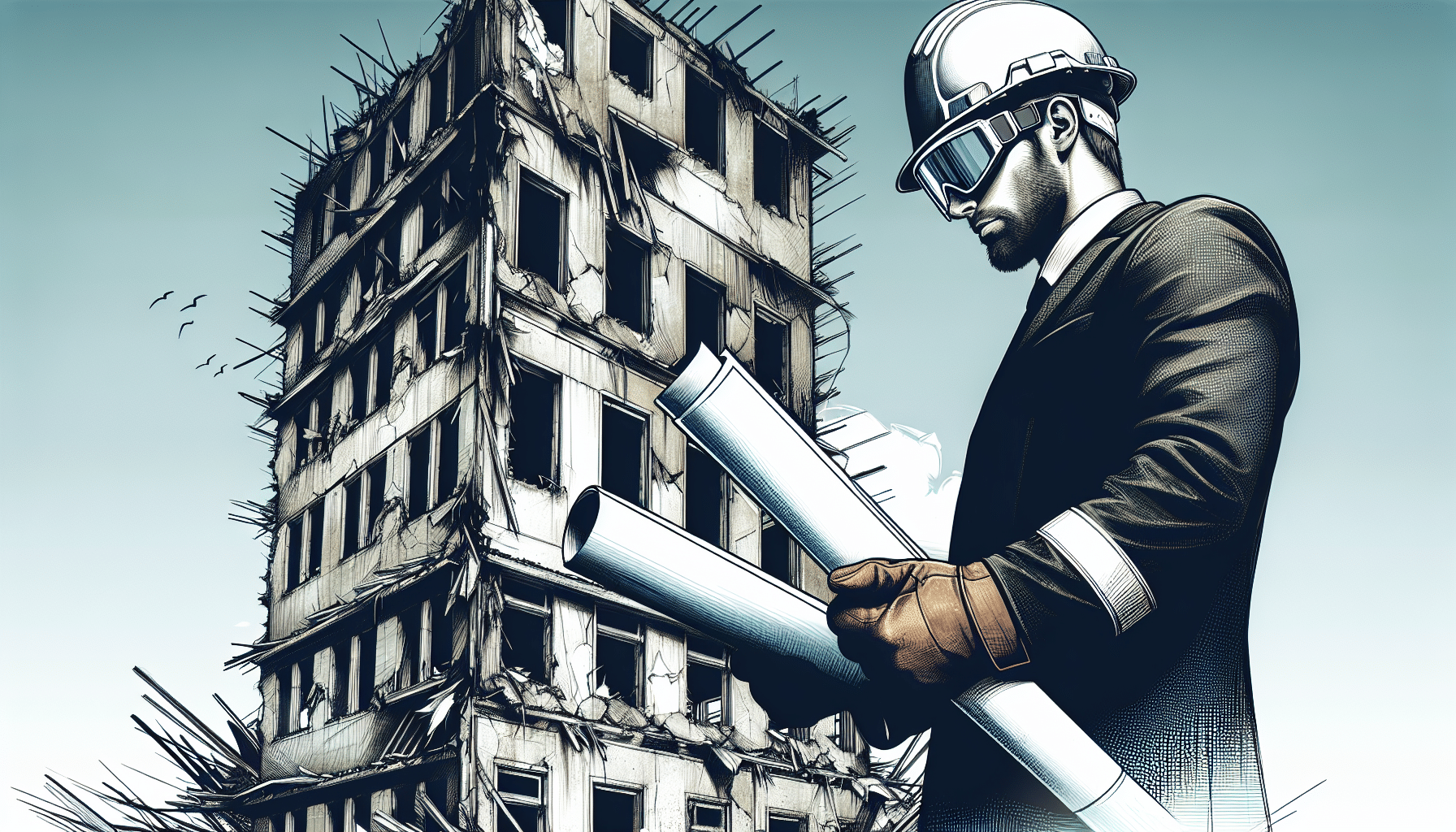

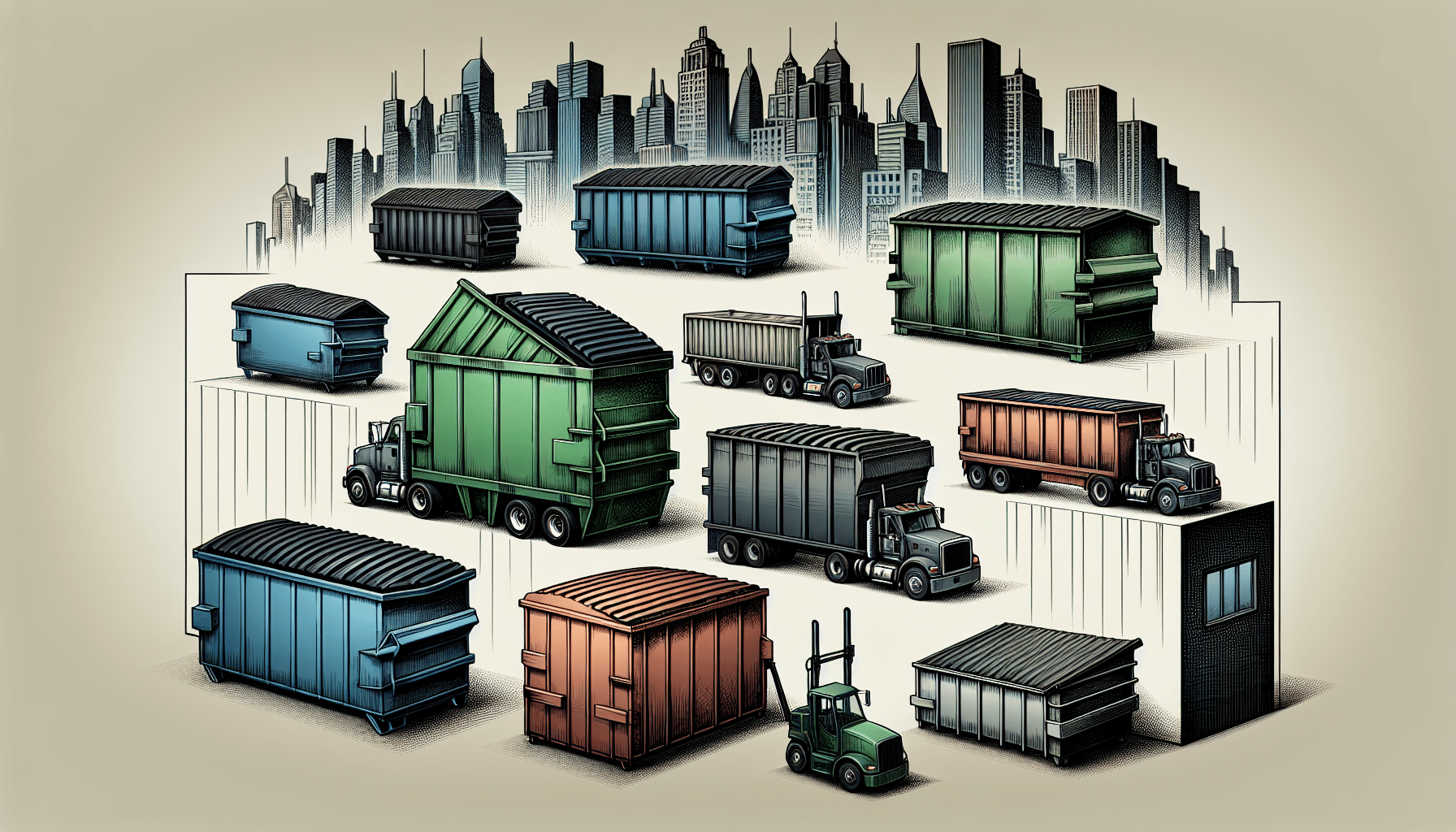

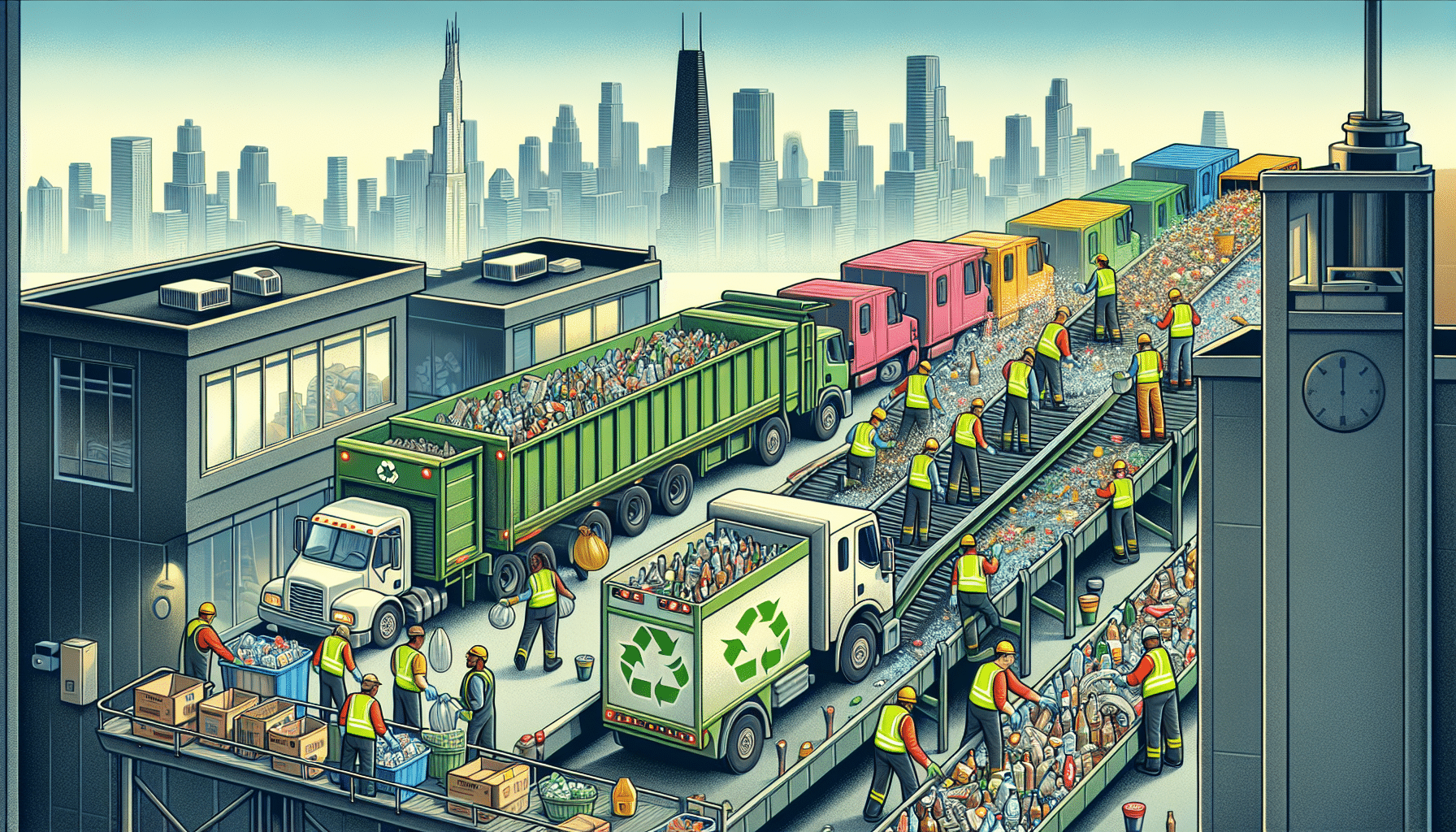

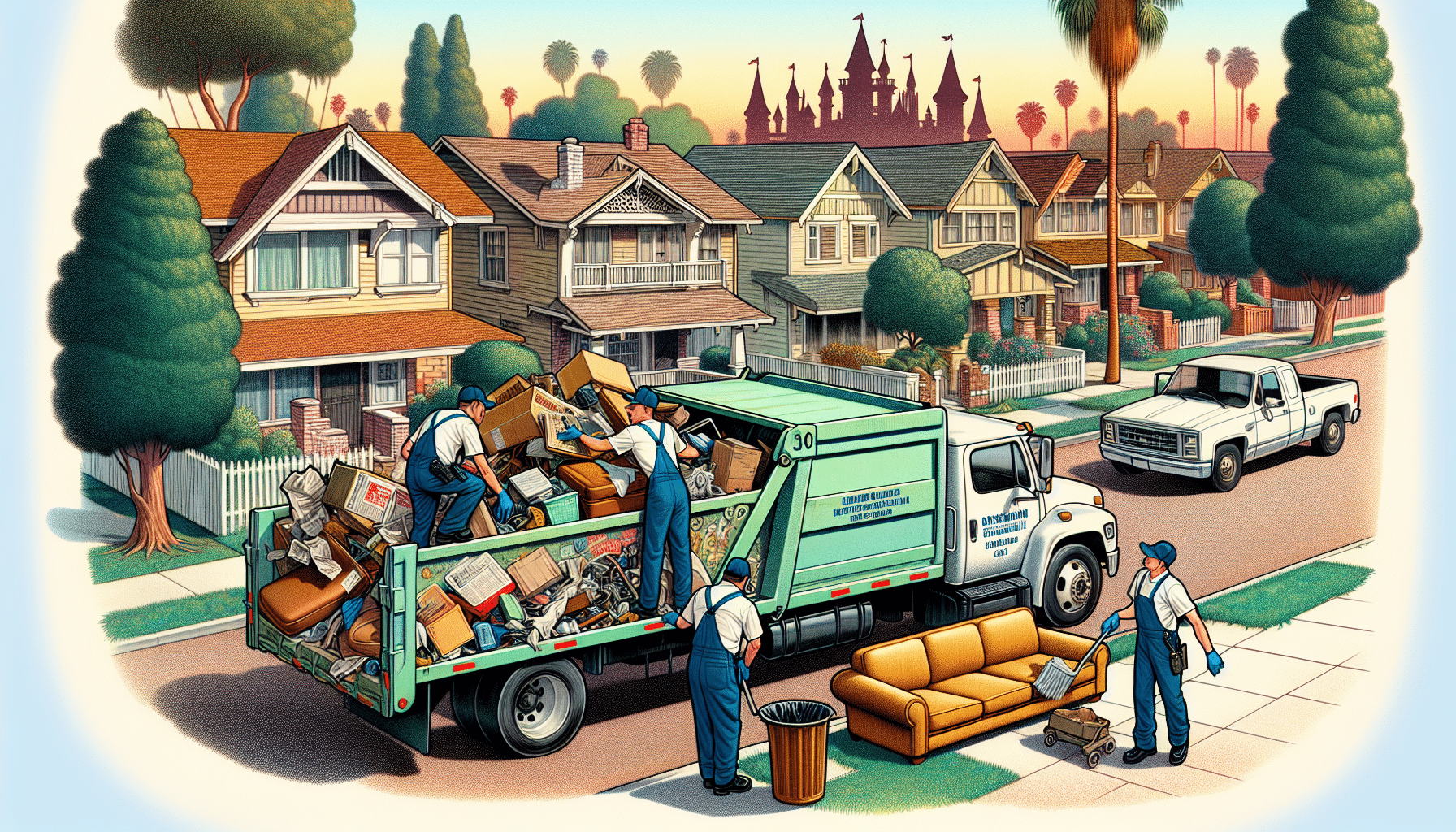

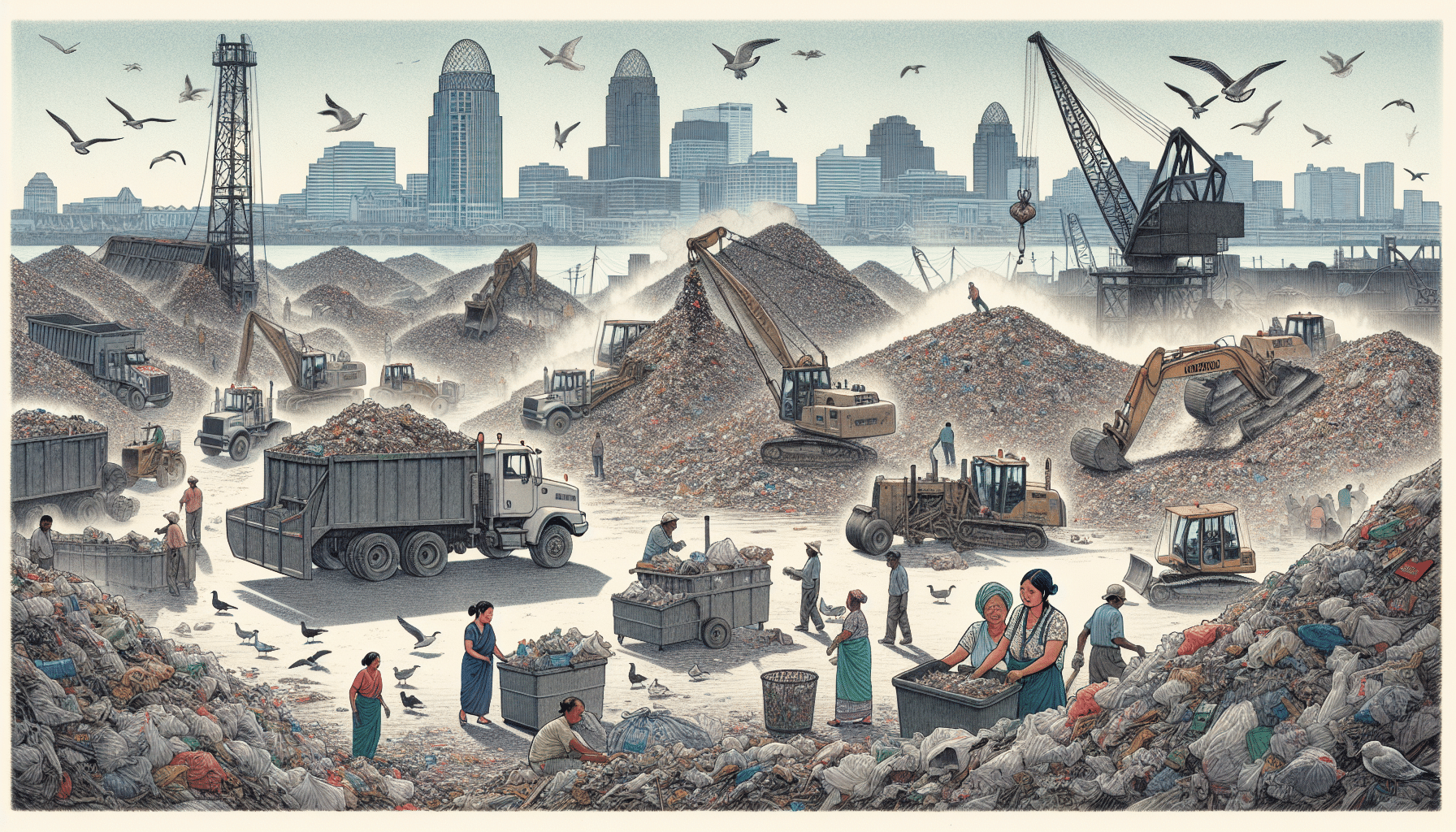

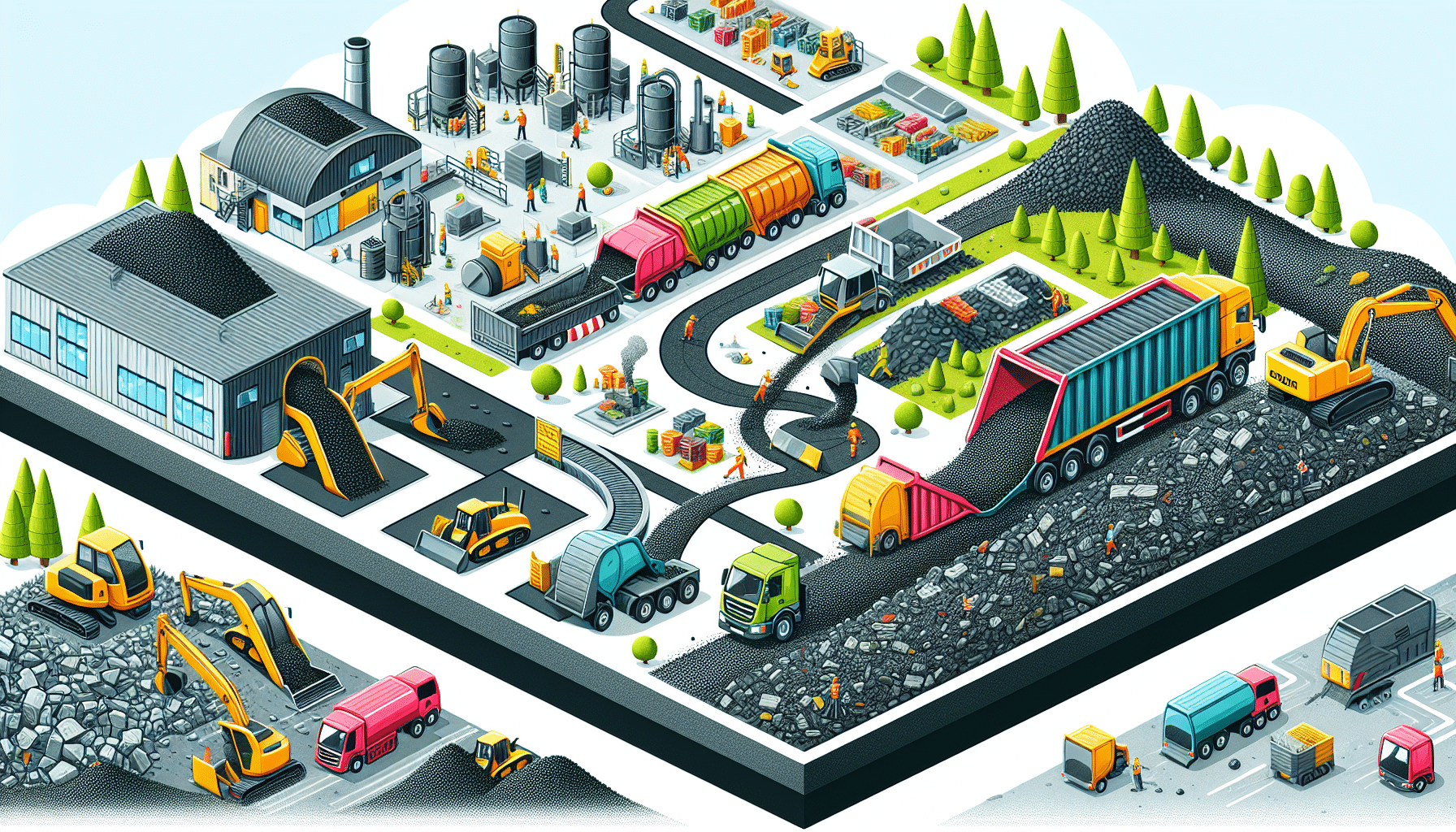

In the bustling streets of the first city, amidst the ever-changing skyline, the method we choose for building removal carries significant weight. Deconstruction, a concept that emerged in the 1990s and gained prominence by the end of the decade, is now leading the charge as a more sustainable alternative to demolition. It’s a transformative approach that allows us to salvage and repurpose materials, enriching our environment and economy in ways we’re only beginning to explore.

This journey through residential demolition and deconstruction will unveil its essence, its advantages over traditional demolition, and the best practices ensuring its success. Whether you’re a stakeholder on a construction site or simply a curious mind, the insights shared here will reshape your understanding of how we can responsibly bid farewell to the buildings that once defined our communities.

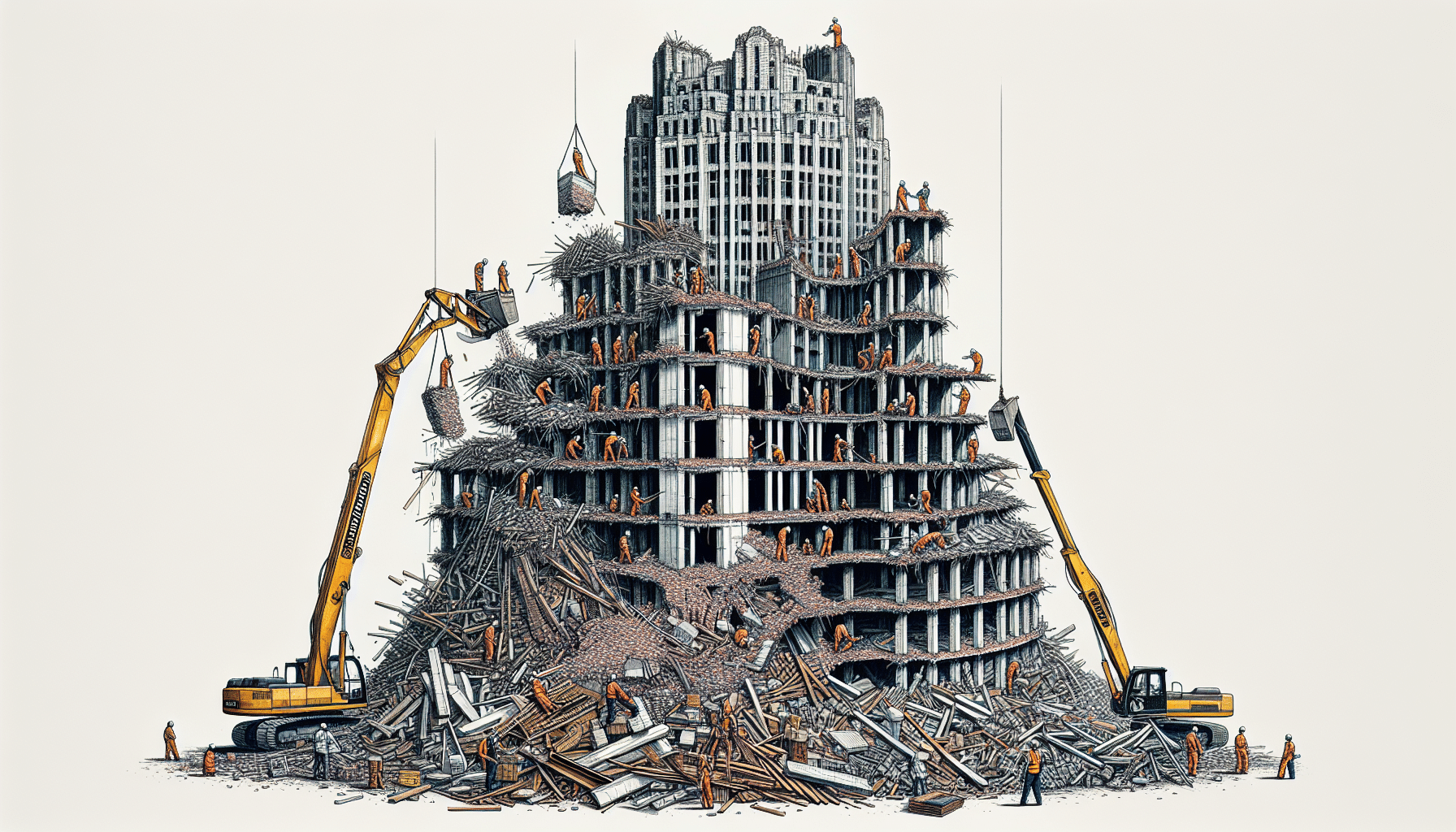

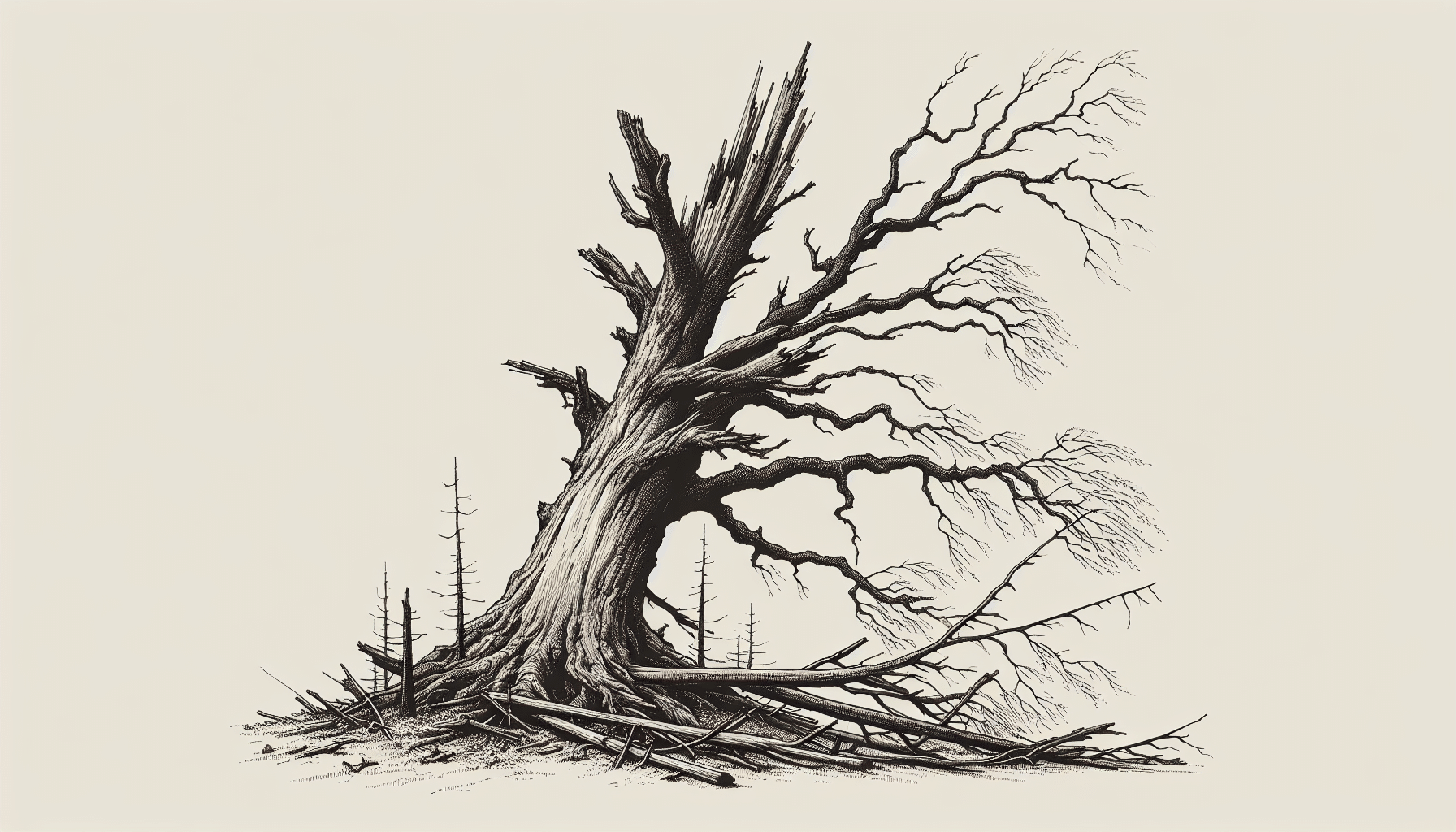

Understanding Deconstruction

As we delve into the deconstruction process, we must recognize its role as a beacon of sustainability in building removal. Unlike the brute force of mechanical demolition, deconstruction is a thoughtful, selective approach that conserves resources and honors the lifecycle of building materials. It’s a path less traveled that offers a treasure trove of benefits waiting to be unearthed by those willing to look beyond the rubble of traditional demolition.

What is Deconstruction?

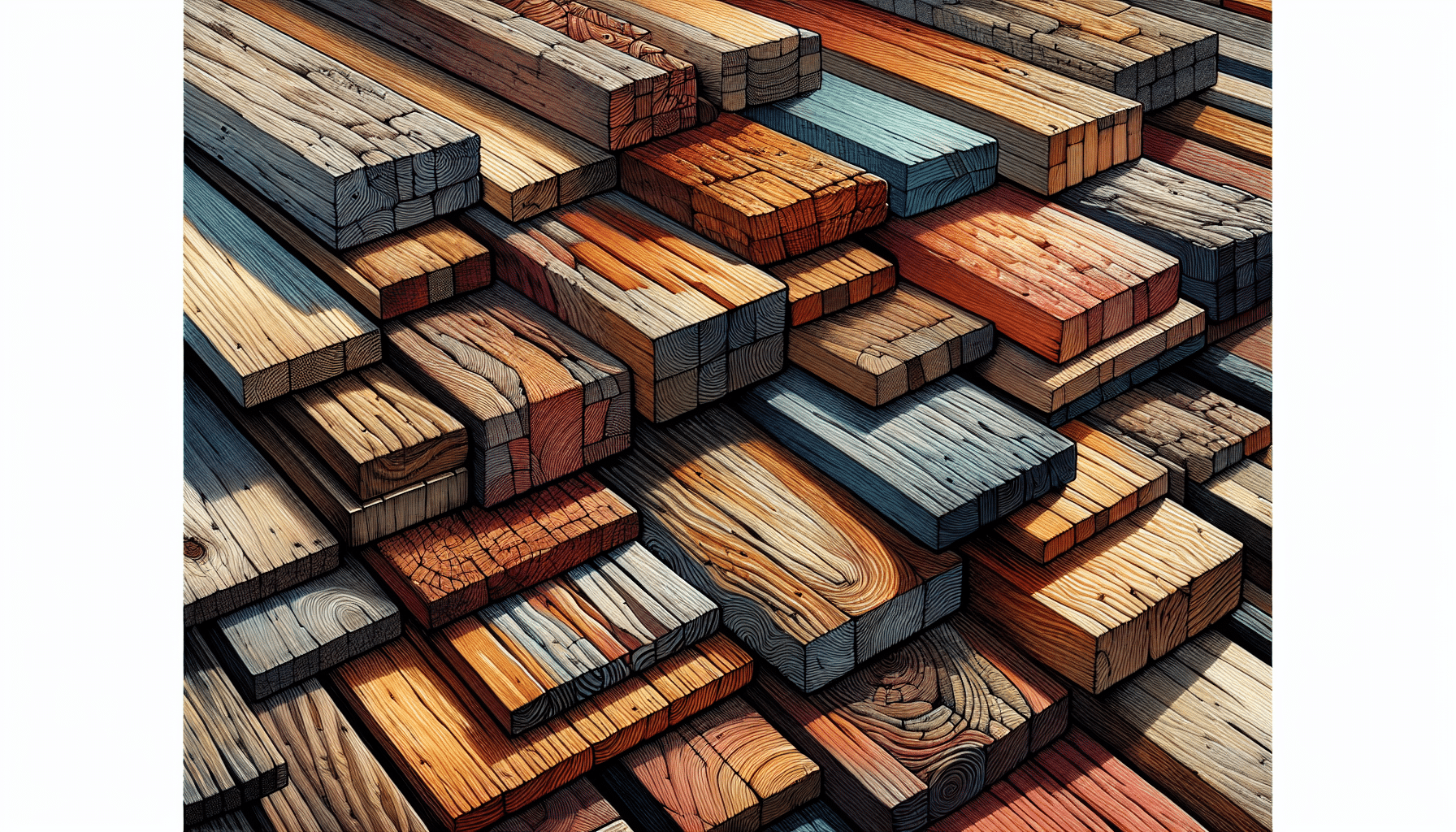

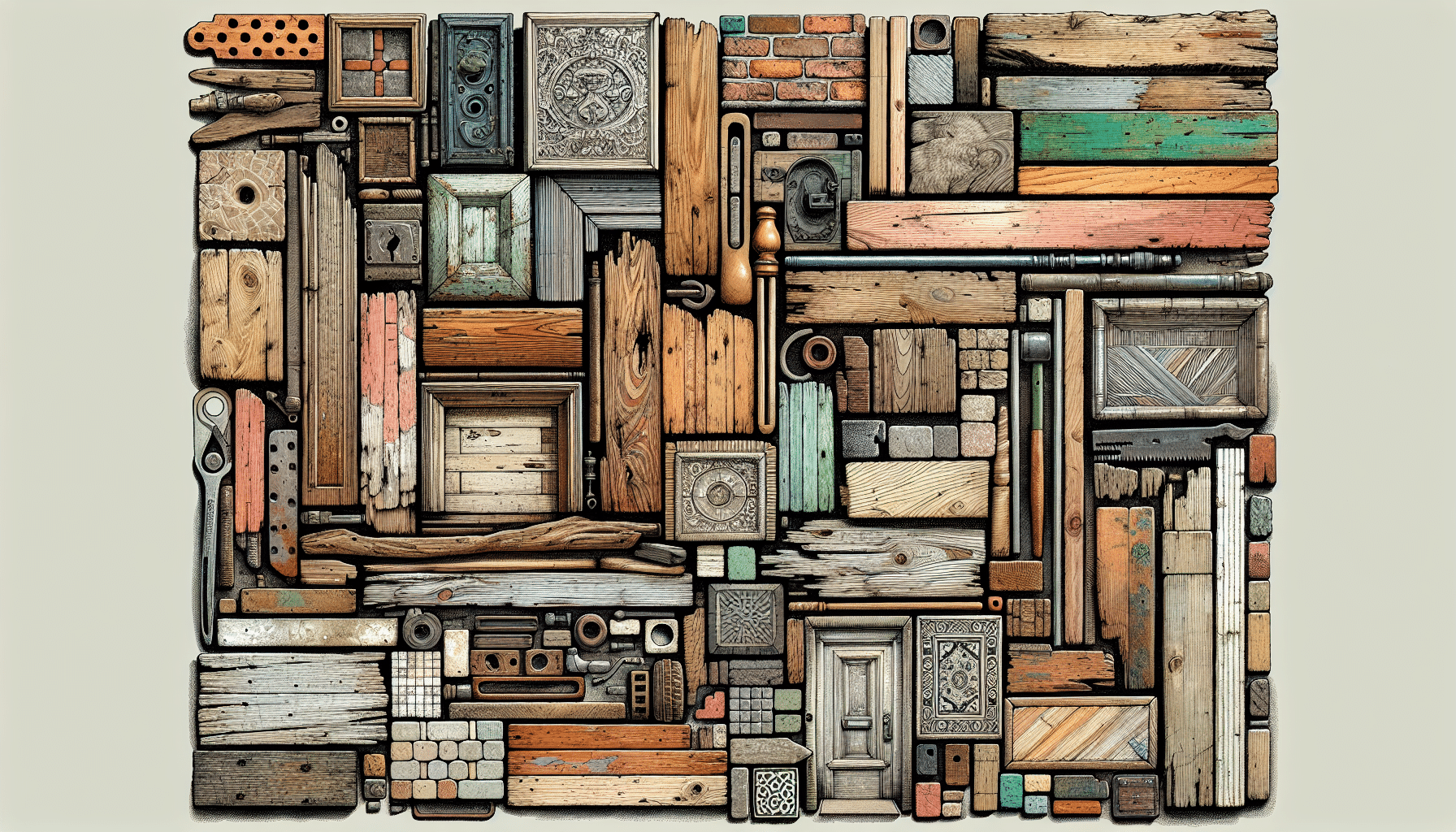

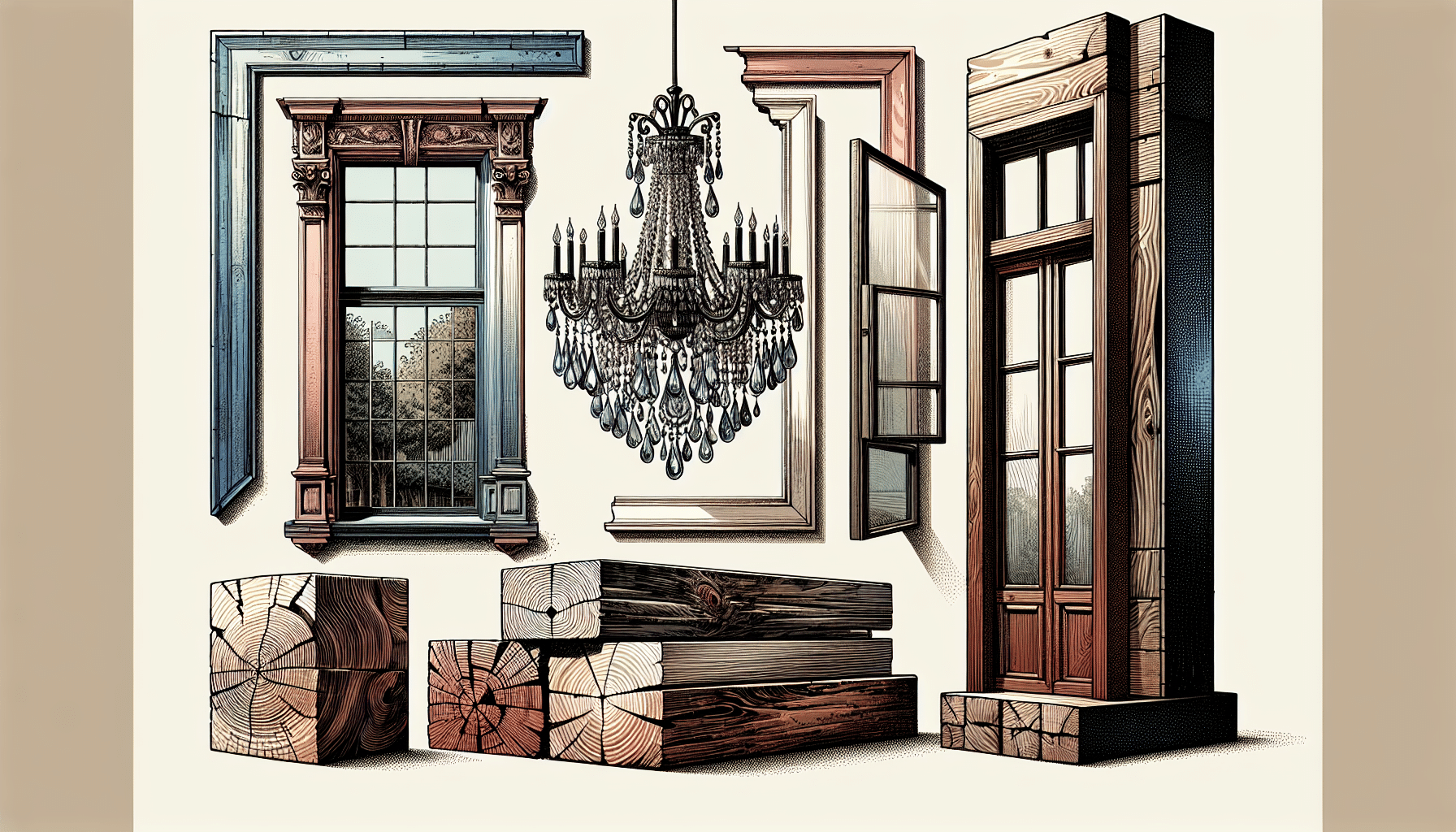

Deconstruction is the very antithesis of conventional demolition. It’s a meticulous ballet, where each movement is intentional, each step carefully planned to ensure the preservation and subsequent reuse of building components. This process safeguards valuable materials and preserves the cultural narratives woven into the fabric of historic structures.

Imagine a world where buildings are not merely torn down but are thoroughly deconstructed, with their essence captured and reborn in new forms. This is the essence of building deconstruction, a process that aligns with our growing commitment to environmental stewardship and cultural preservation.

Benefits Over Demolition

When we contrast deconstruction with traditional demolition, the advantages become as clear as daylight. Where demolition sees an end, deconstruction sees an opportunity – an opportunity to:

- reduce construction waste

- breathe new life into reusable building materials

- diminish the environmental impact that has long been an accepted byproduct of building removal.

Deconstruction is not just about tearing down; it’s about building up – communities, economies, and a sustainable future. It’s about:

- job creation

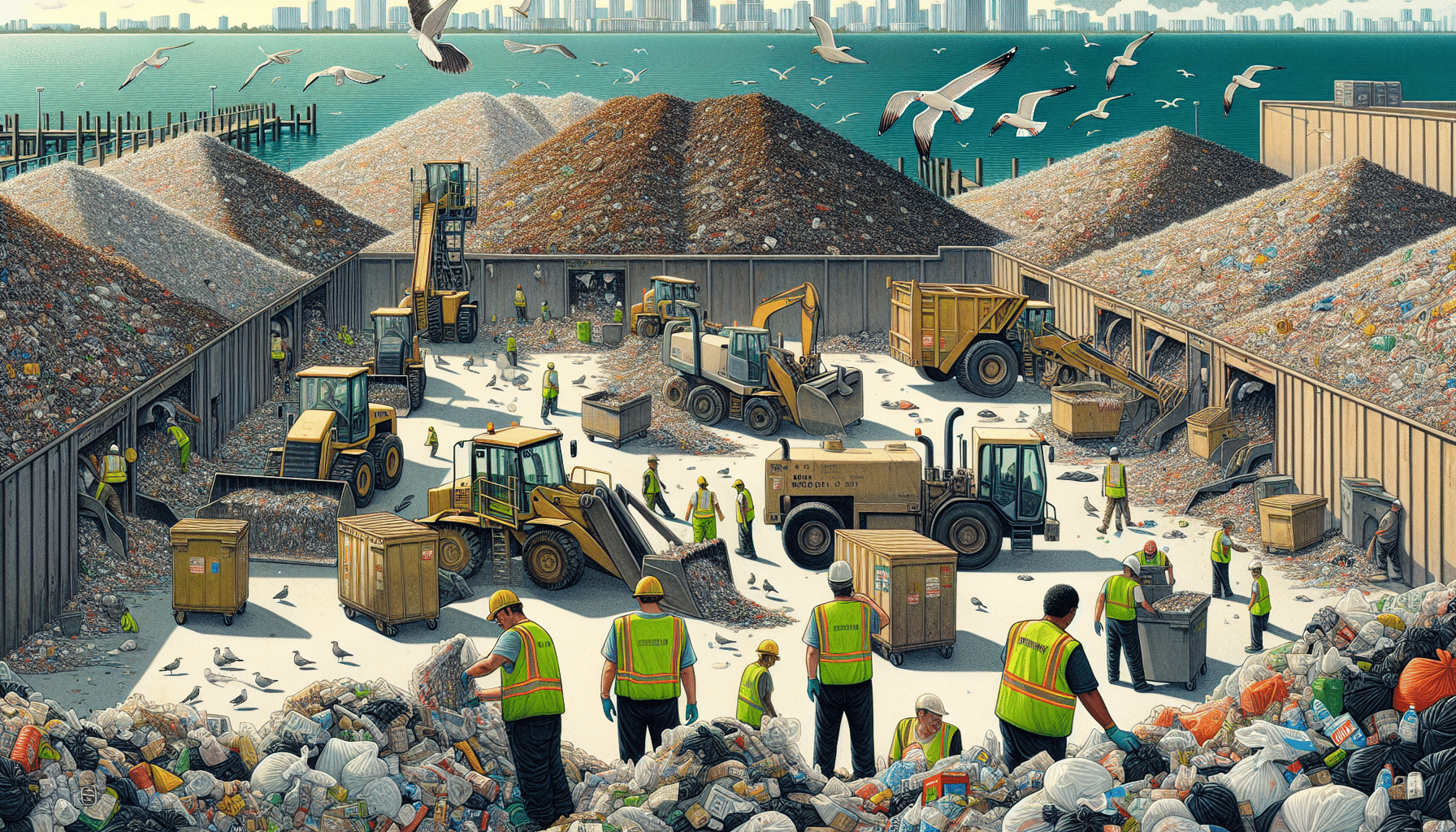

- reduced disposal costs

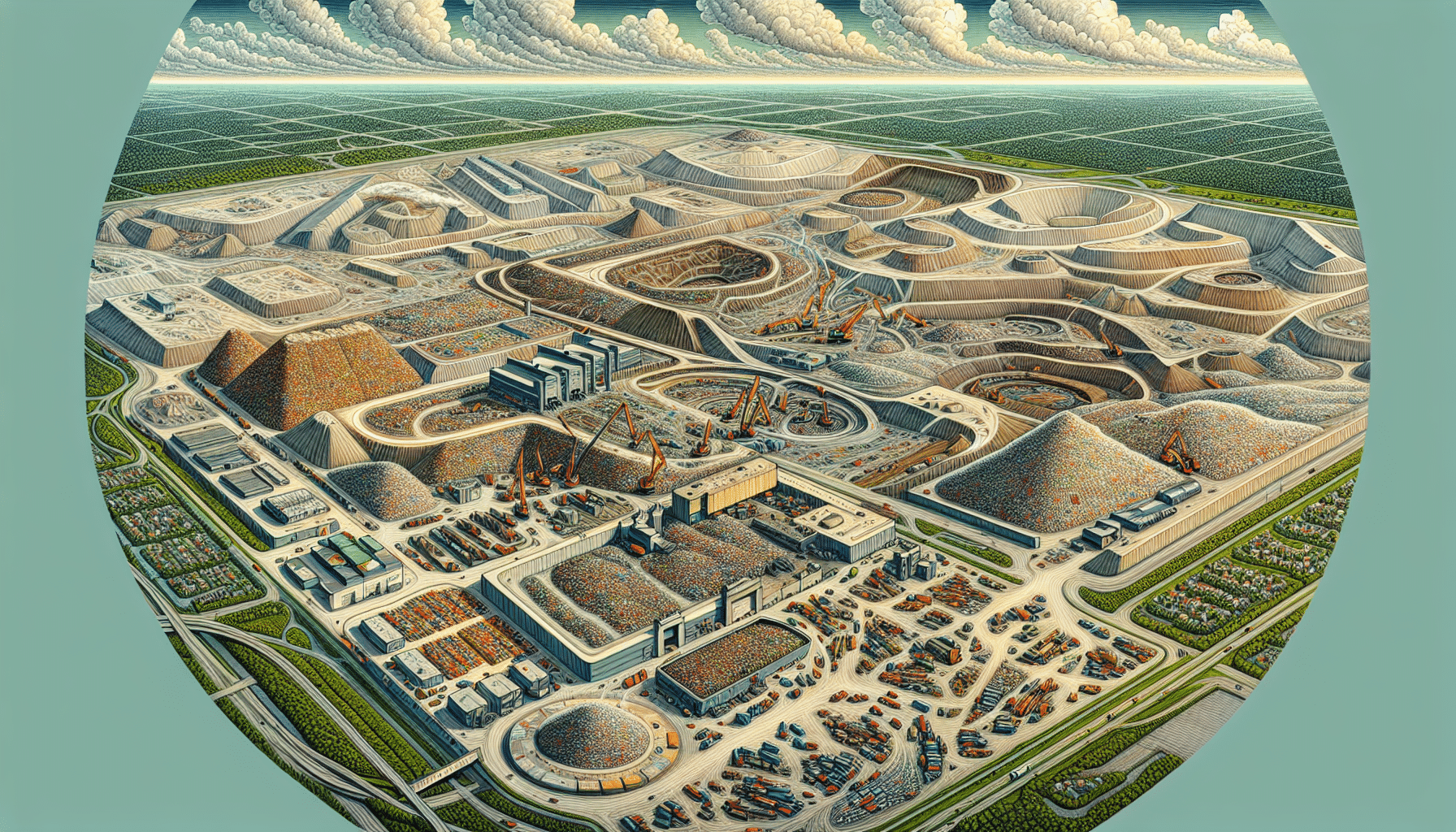

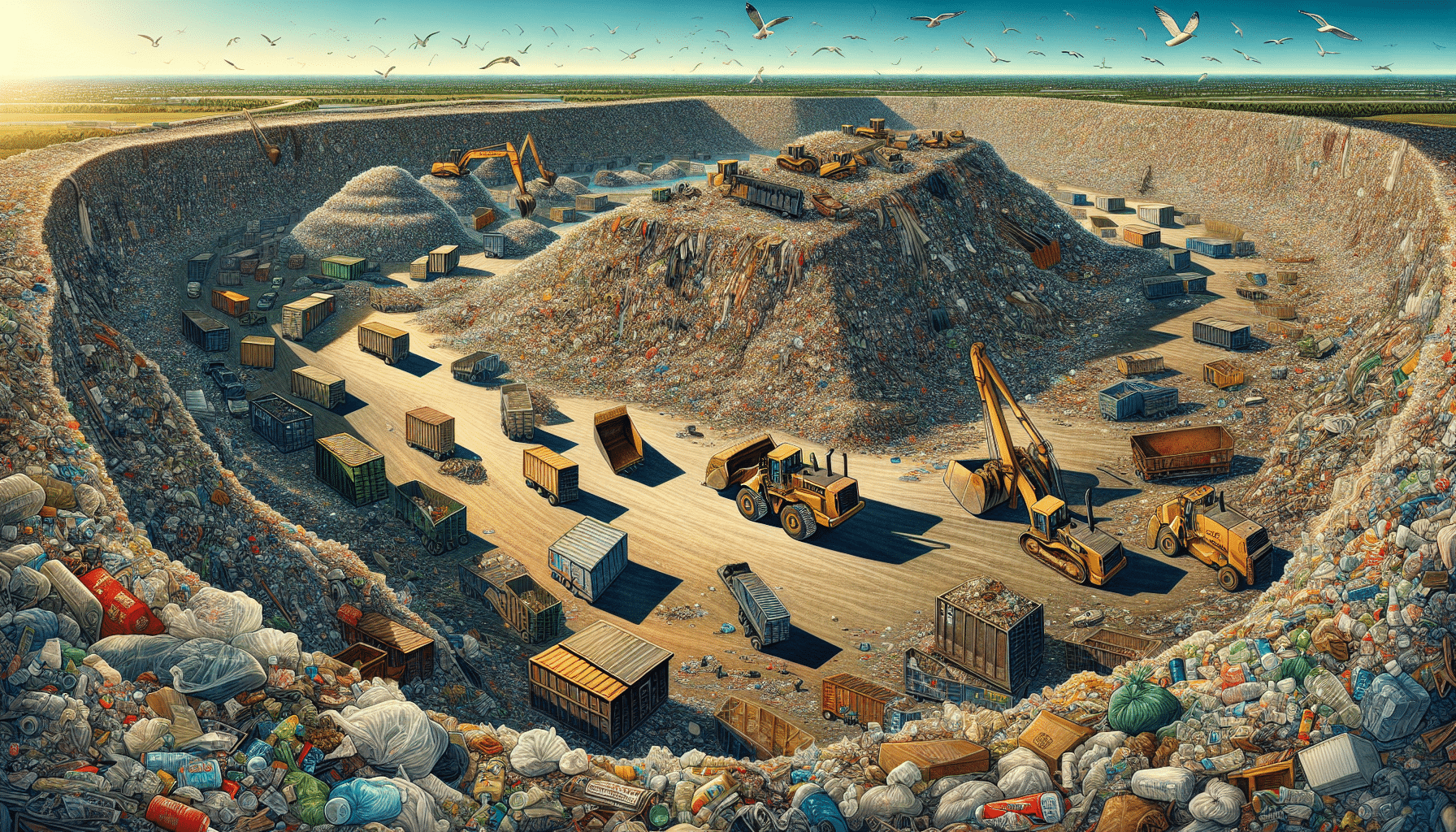

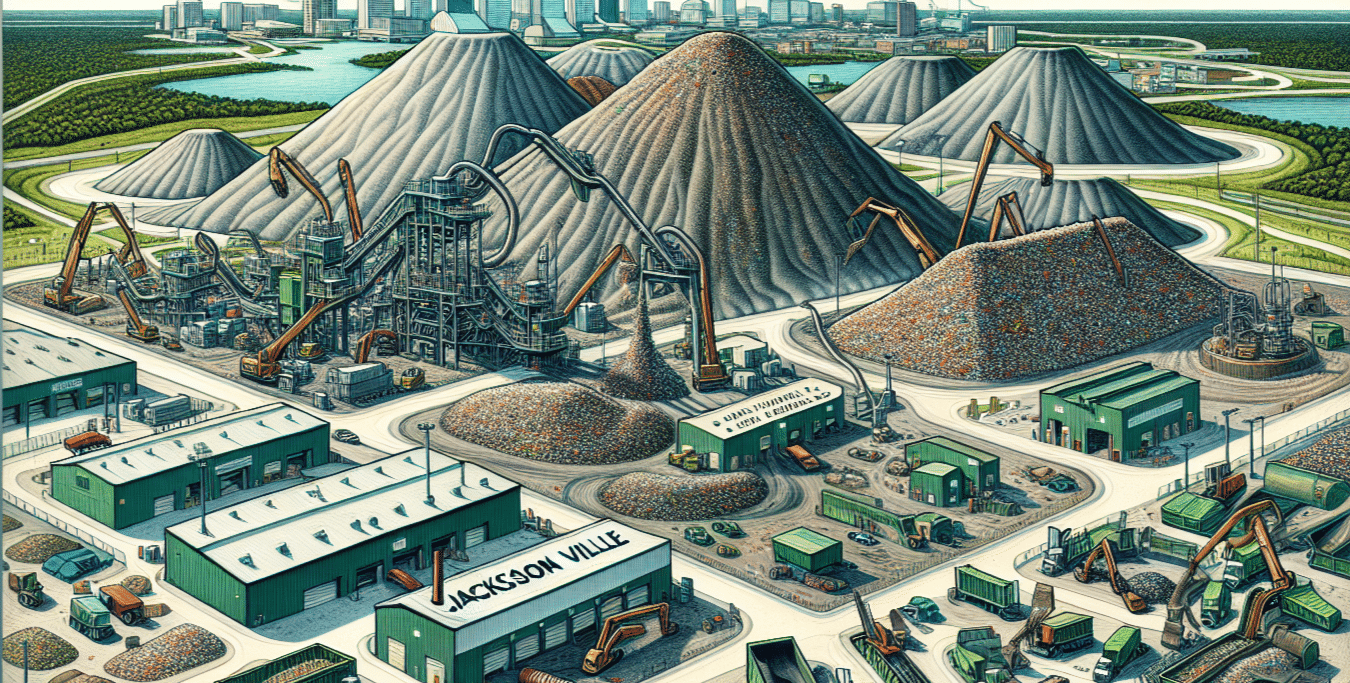

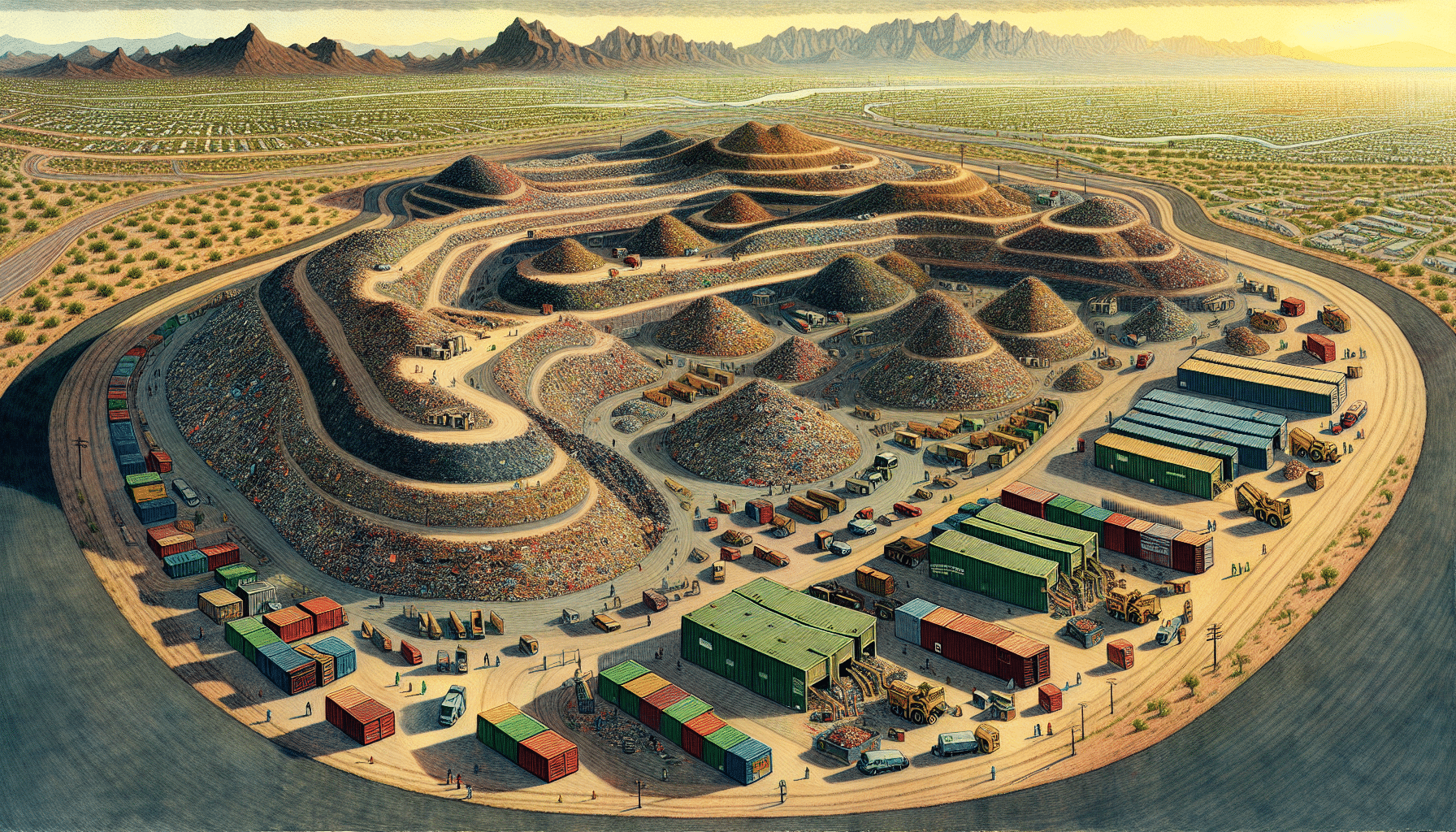

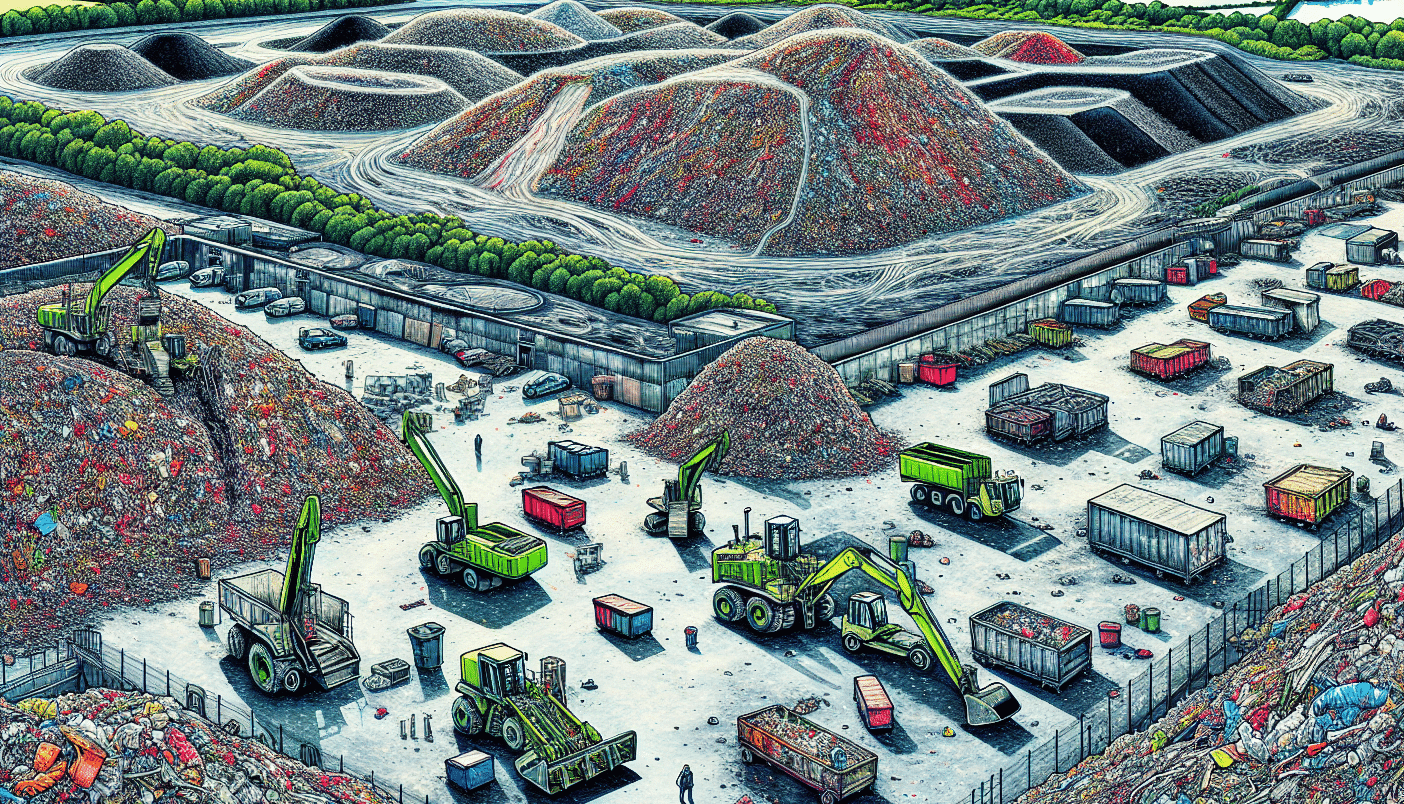

- the innovative reuse of materials that would otherwise contribute to the mounting piles of demolition debris in our landfills

It’s a testament to the power of a hand demolition approach that values every nail, brick, and beam as a potential part of something new.

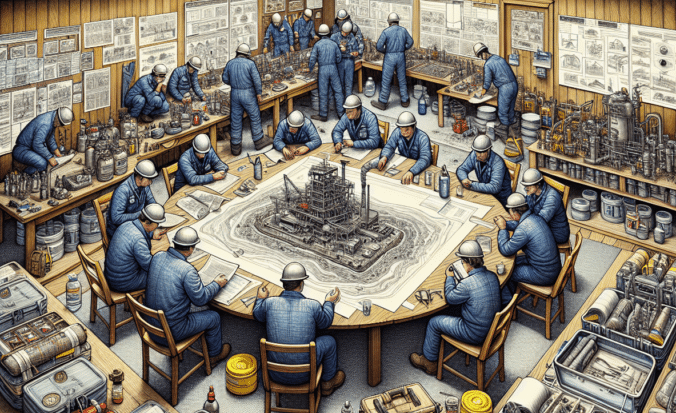

Key Components of a Successful Deconstruction Project

A successful deconstruction project is like a well-orchestrated symphony, where each component is critical in achieving a harmonious outcome. It begins with:

- a deep understanding of the project’s scope

- a commitment to maximizing material salvageability

- certified deconstruction contractors

- efficient inventory management

Every element must align to transform the vision of sustainable building removal into reality.

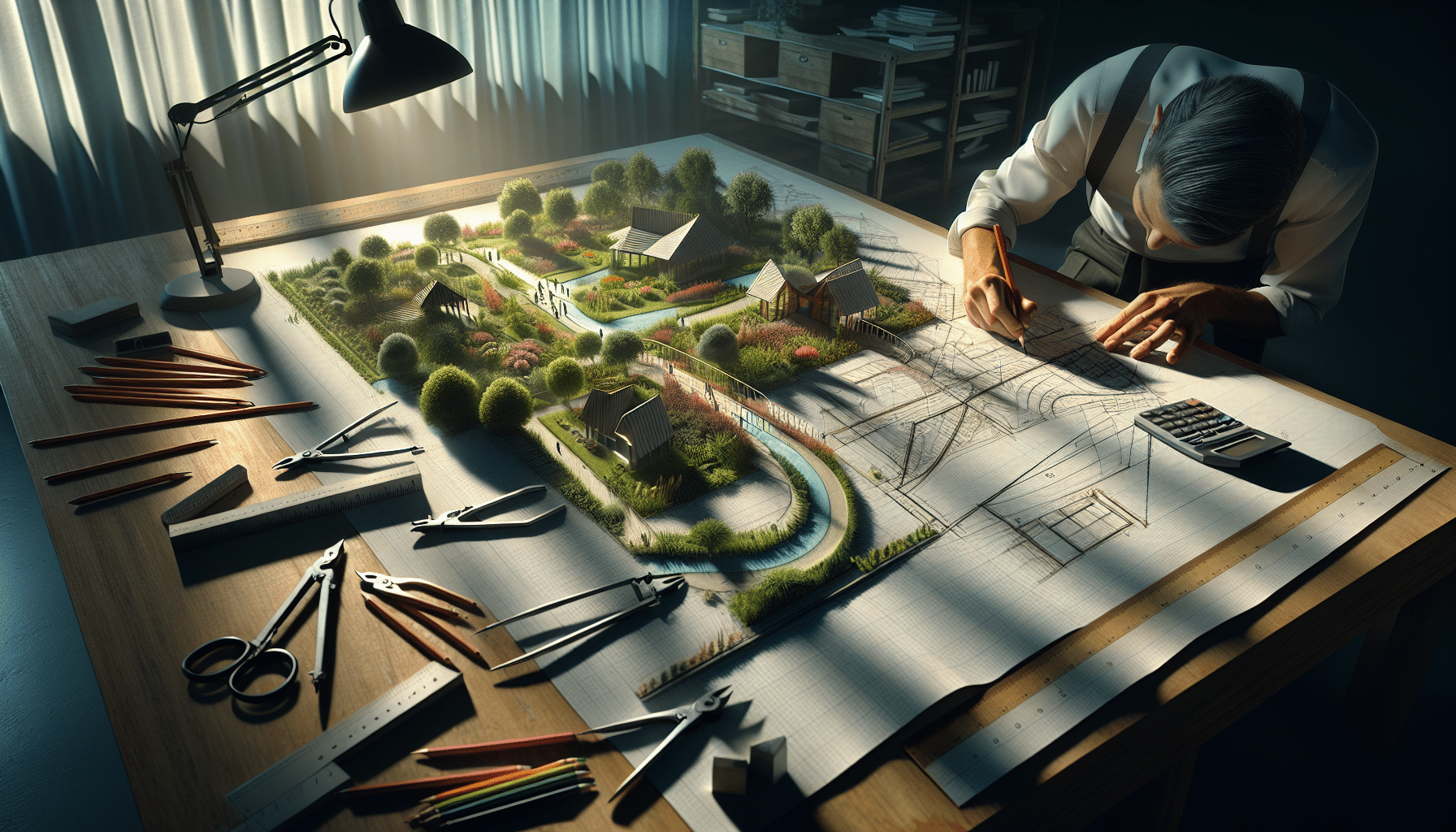

Planning and Assessment

The cornerstone of any deconstruction project is meticulous planning and thorough assessment. It’s about taking the time to:

- sift through demolition drawings

- evaluate the structural integrity of the site

- pinpoint the valuable materials that hold the key to successful material salvage

This stage is not a mere formality but a crucial foundation determining the project’s trajectory.

By engaging experts from various disciplines, we ensure an accurate and comprehensive deconstruction plan that not only identifies the gems hidden within a structure but also paves the way for their safe and profitable recovery. This process requires foresight and an unwavering dedication to the principles of sustainability and resource conservation principles.

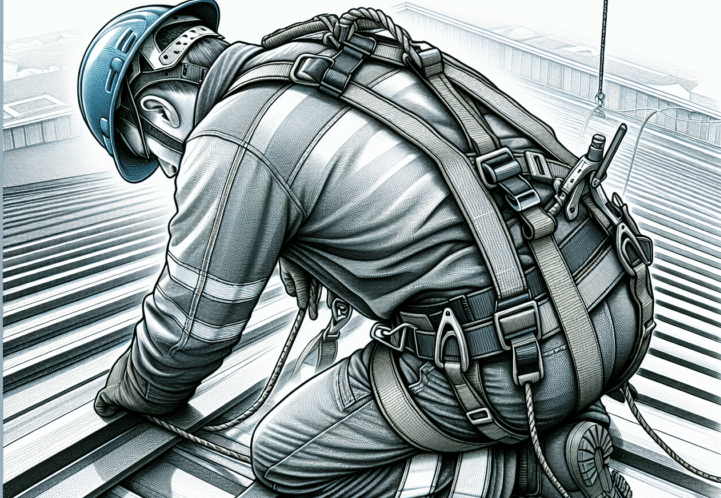

Certified Deconstruction Contractors

In the realm of deconstruction, certified deconstruction contractors are the unsung heroes. Their expertise and commitment to safety regulations are the backbone of a project’s success. These skilled professionals carefully navigate the complexities of dismantling, ensuring that every piece of salvaged material is handled carefully and is ready for its next chapter.

The value of employing certified contractors cannot be overstated. They are the custodians of best practices, upholding the high standards set by local deconstruction ordinances and ensuring compliance with industry regulations. Their work not only maximizes material recovery but also upholds the integrity of the deconstruction process.

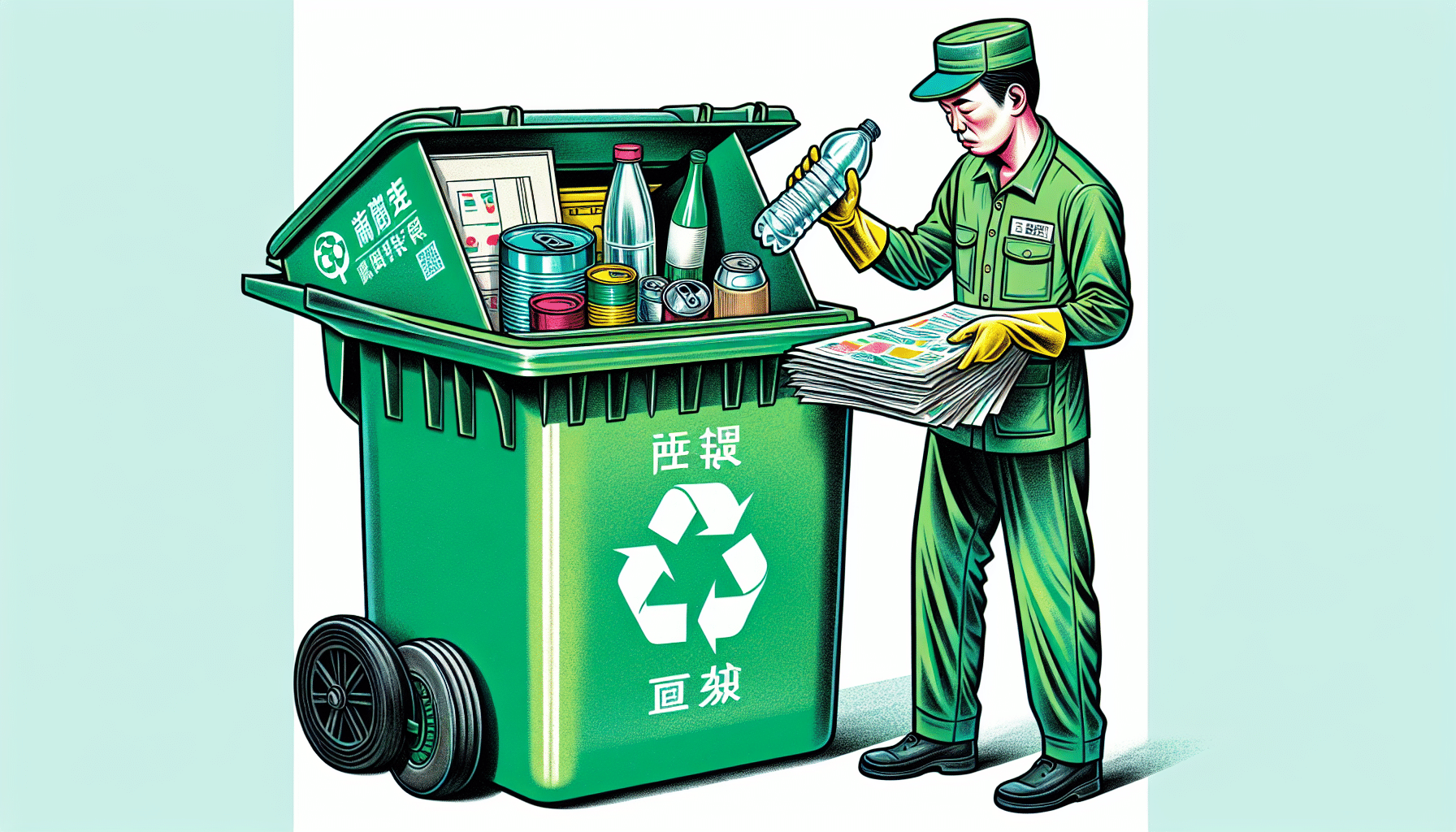

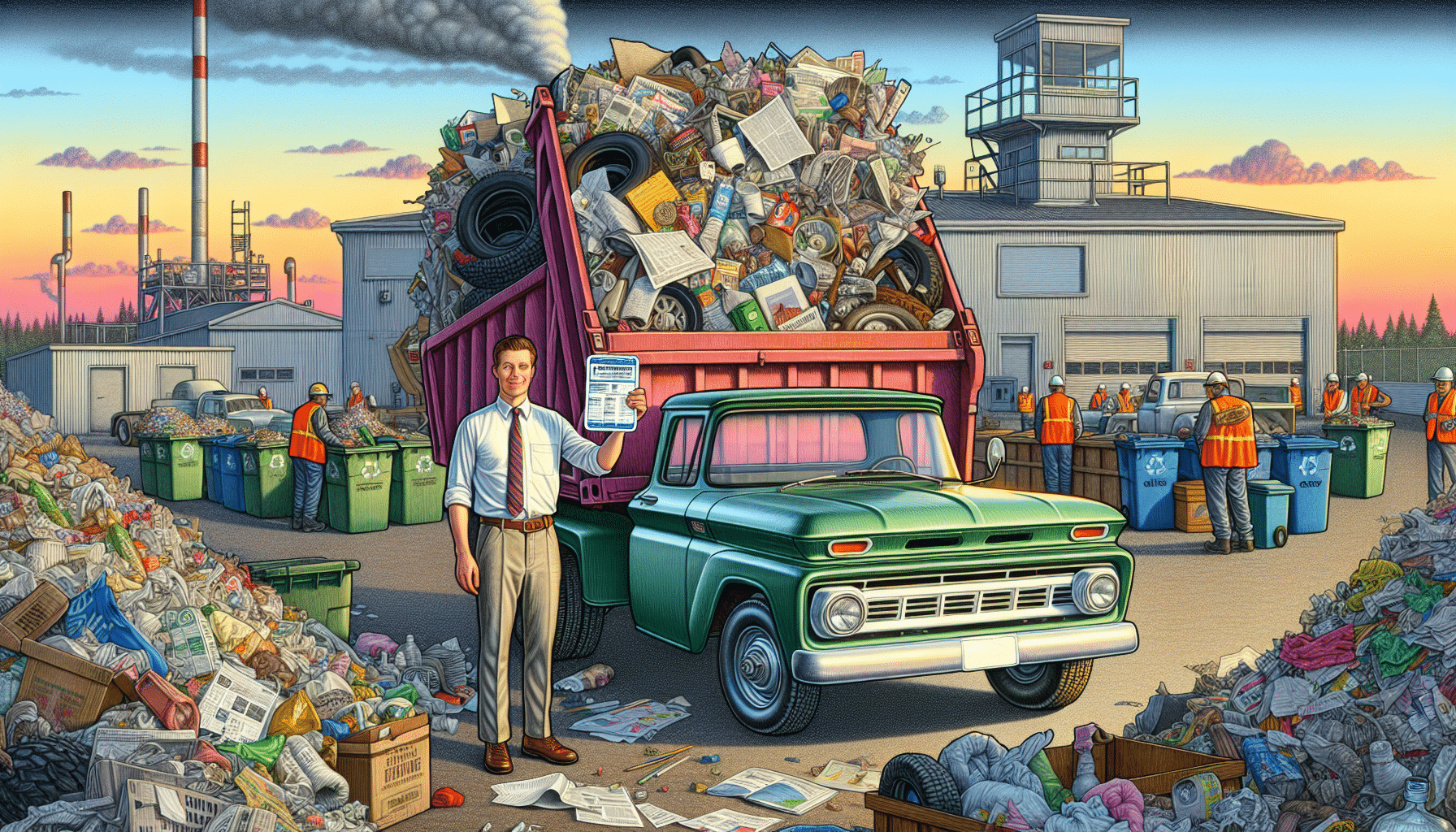

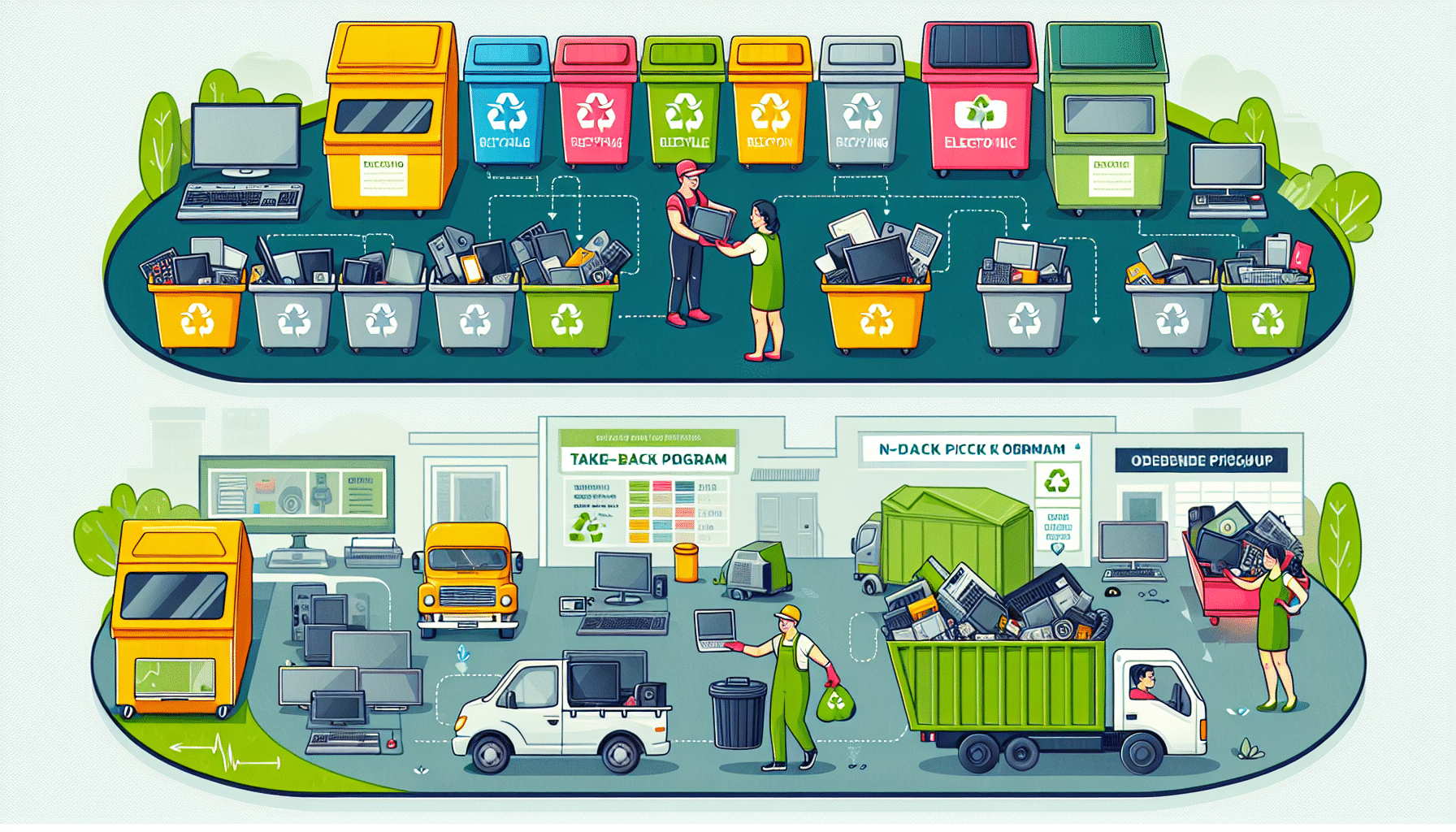

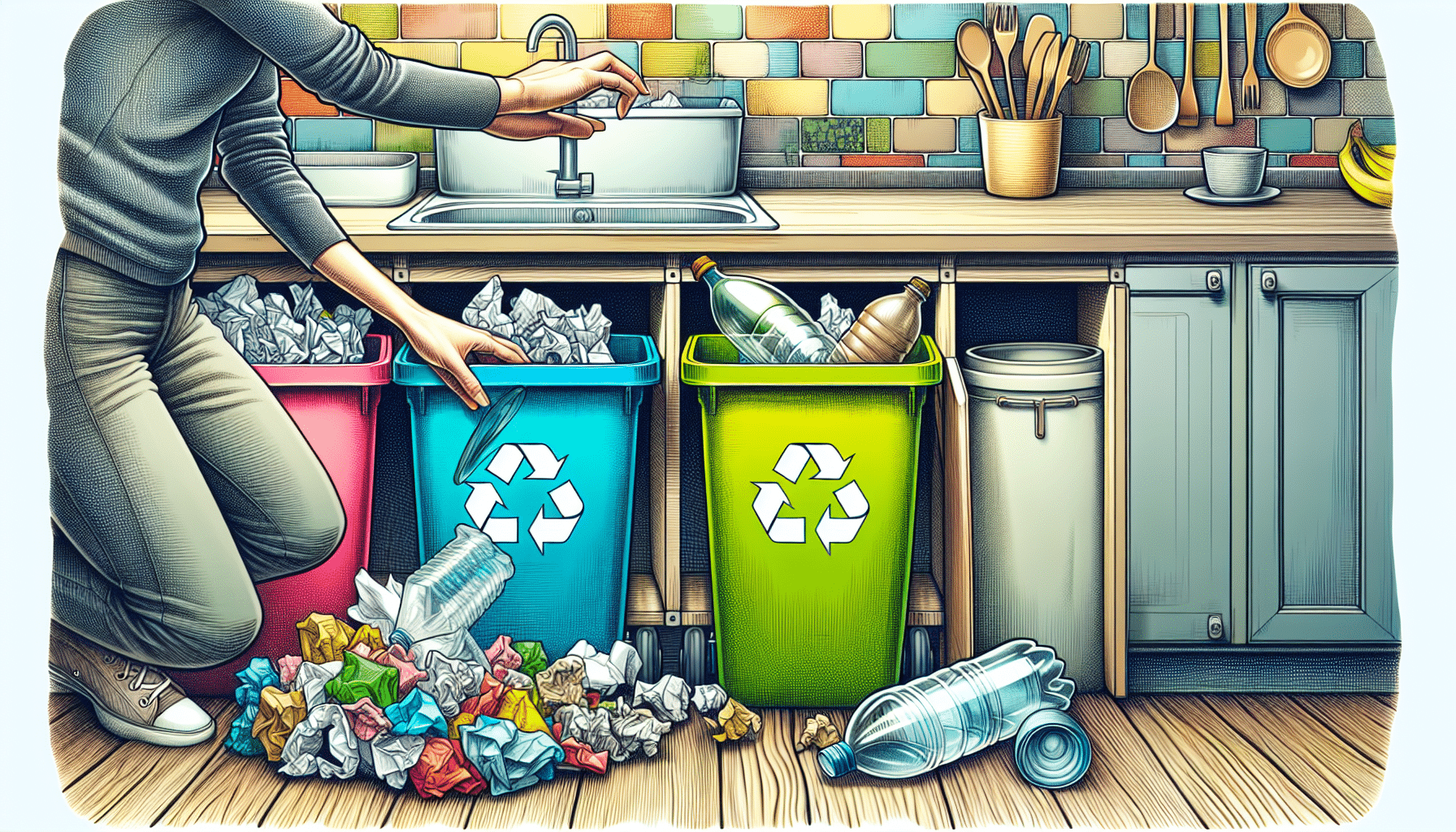

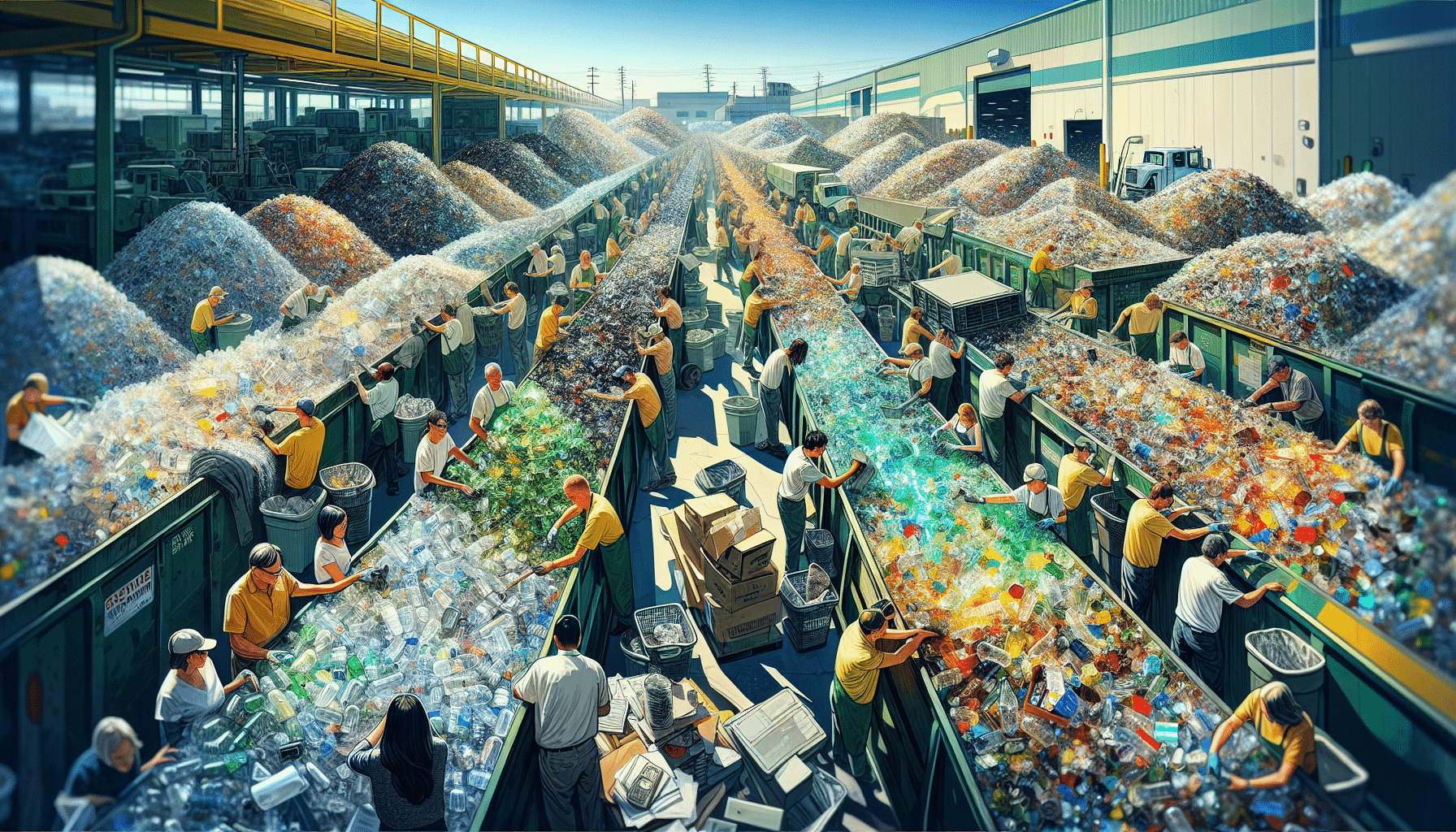

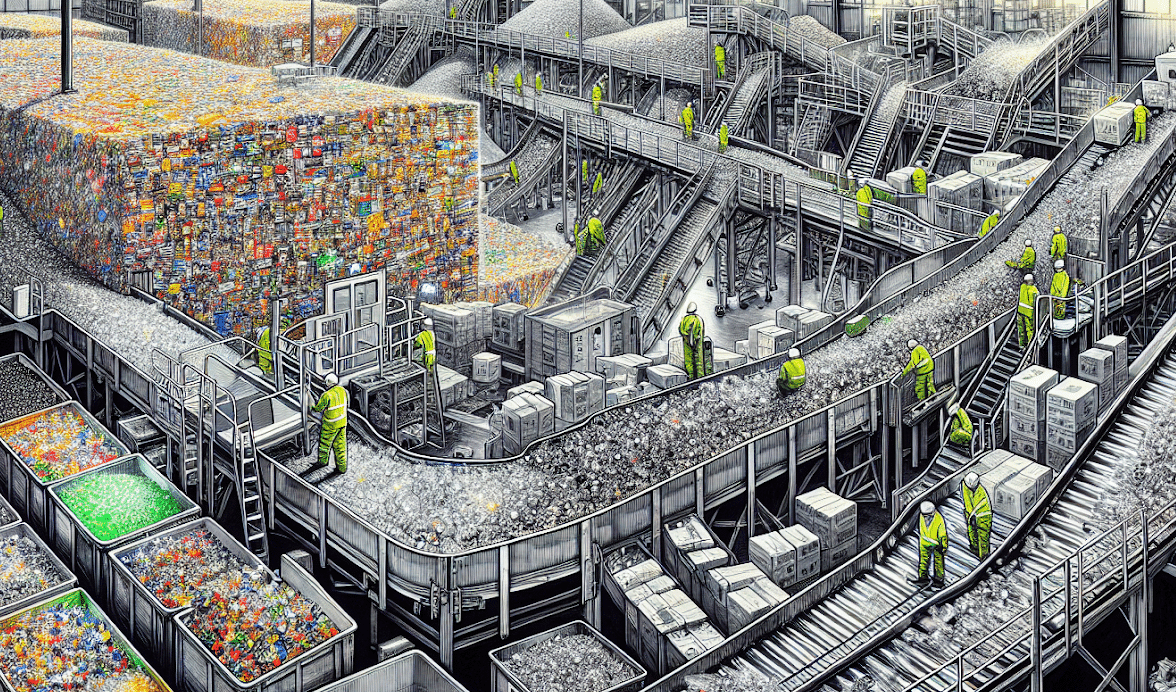

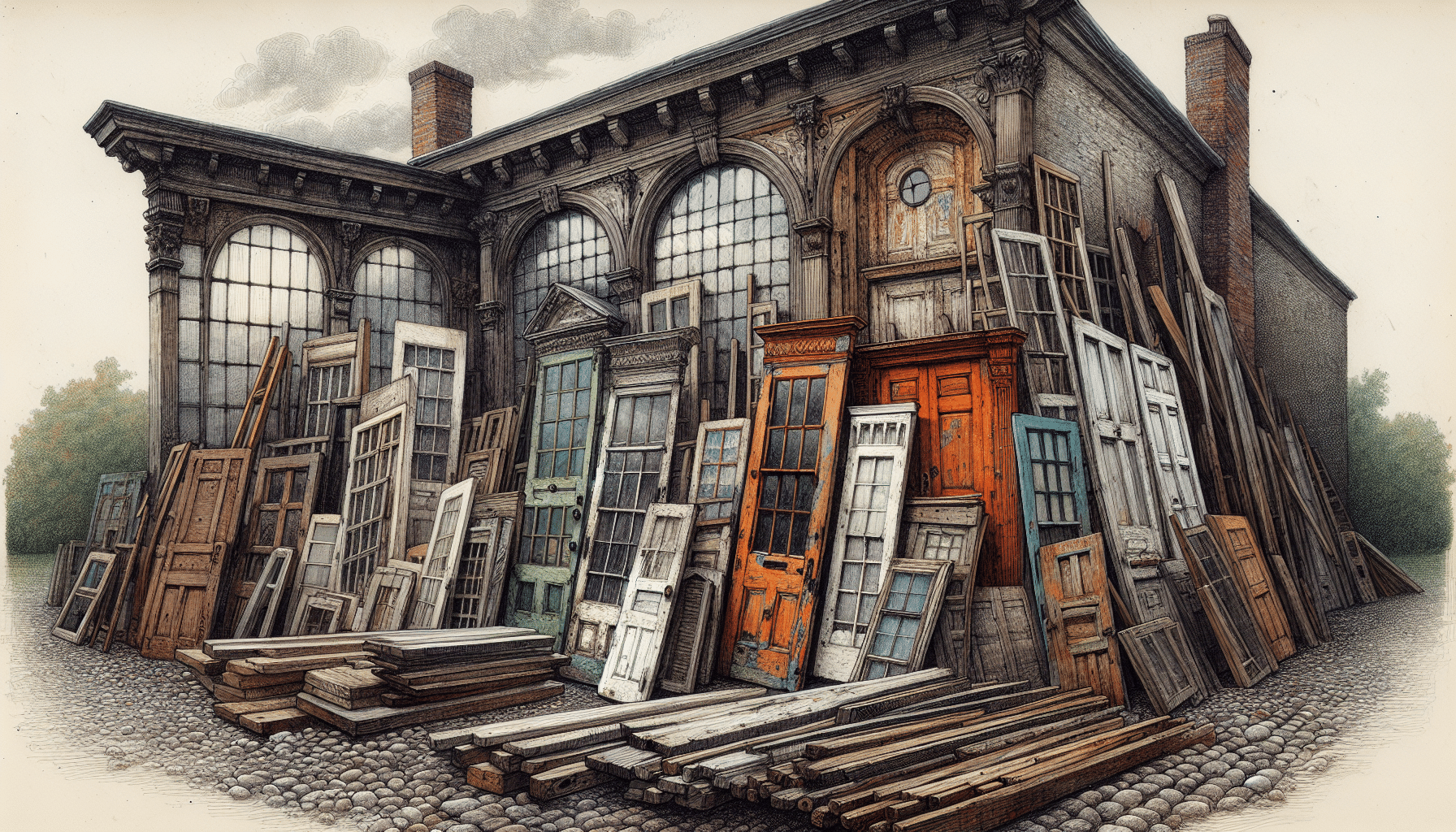

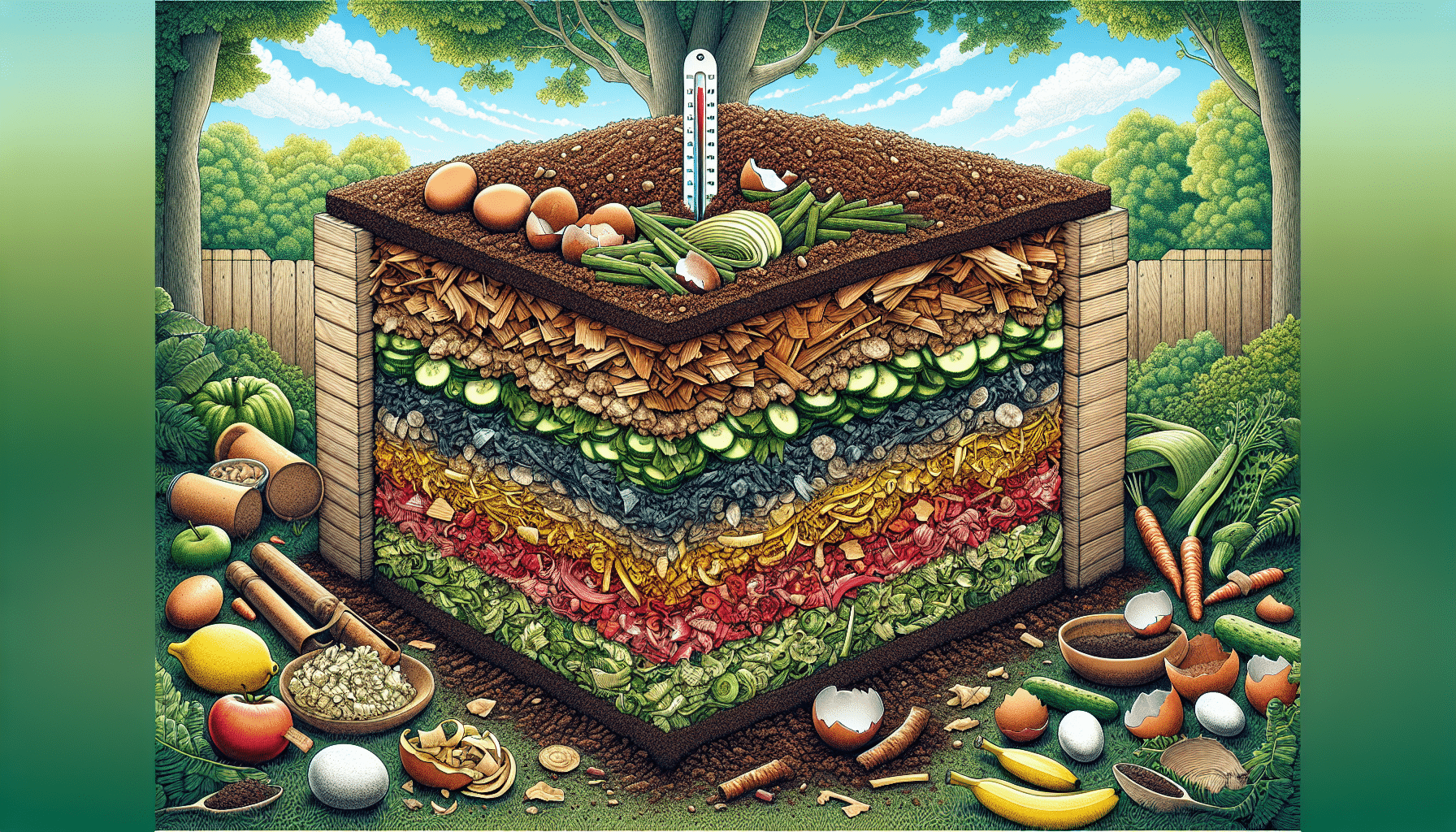

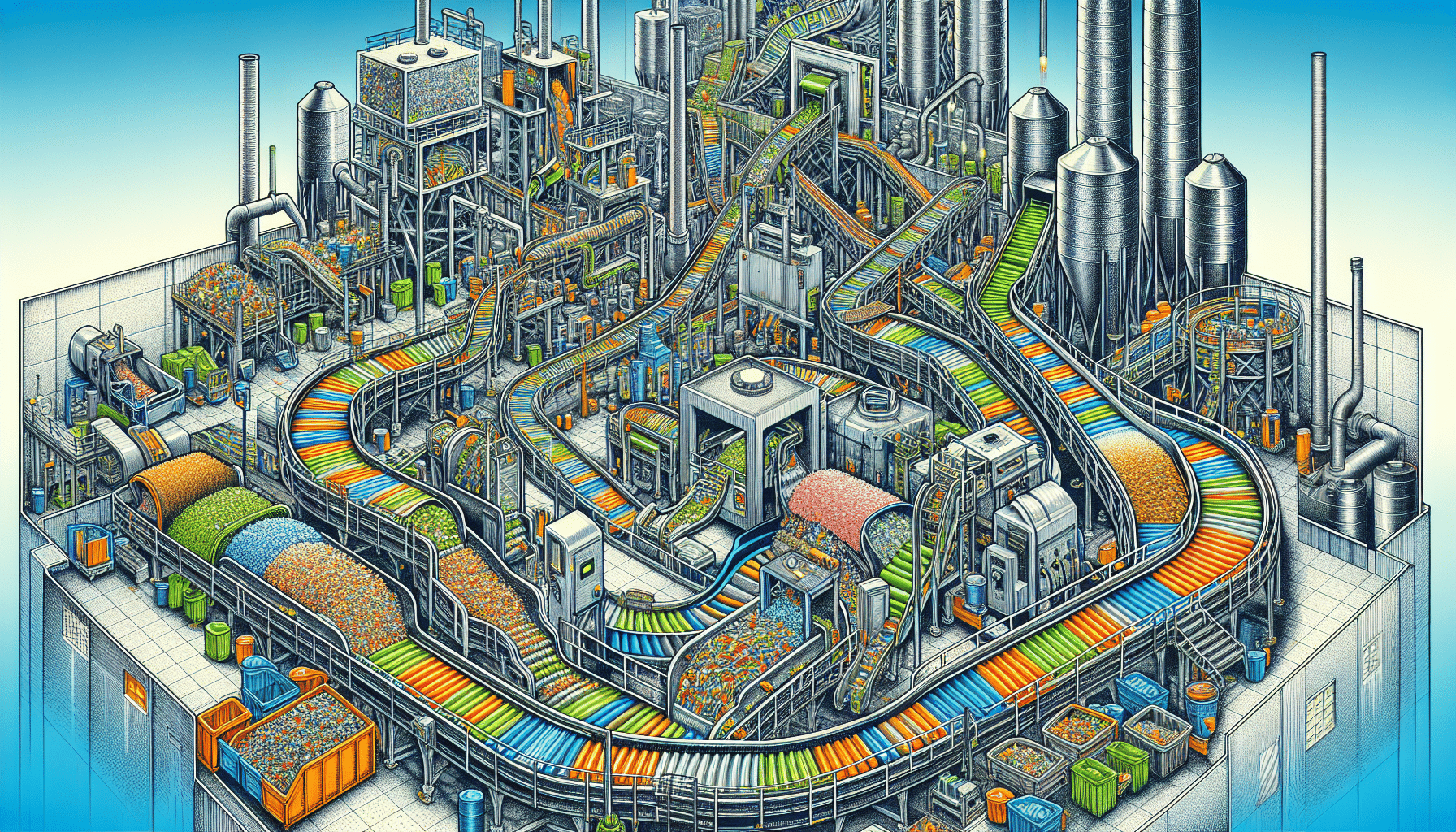

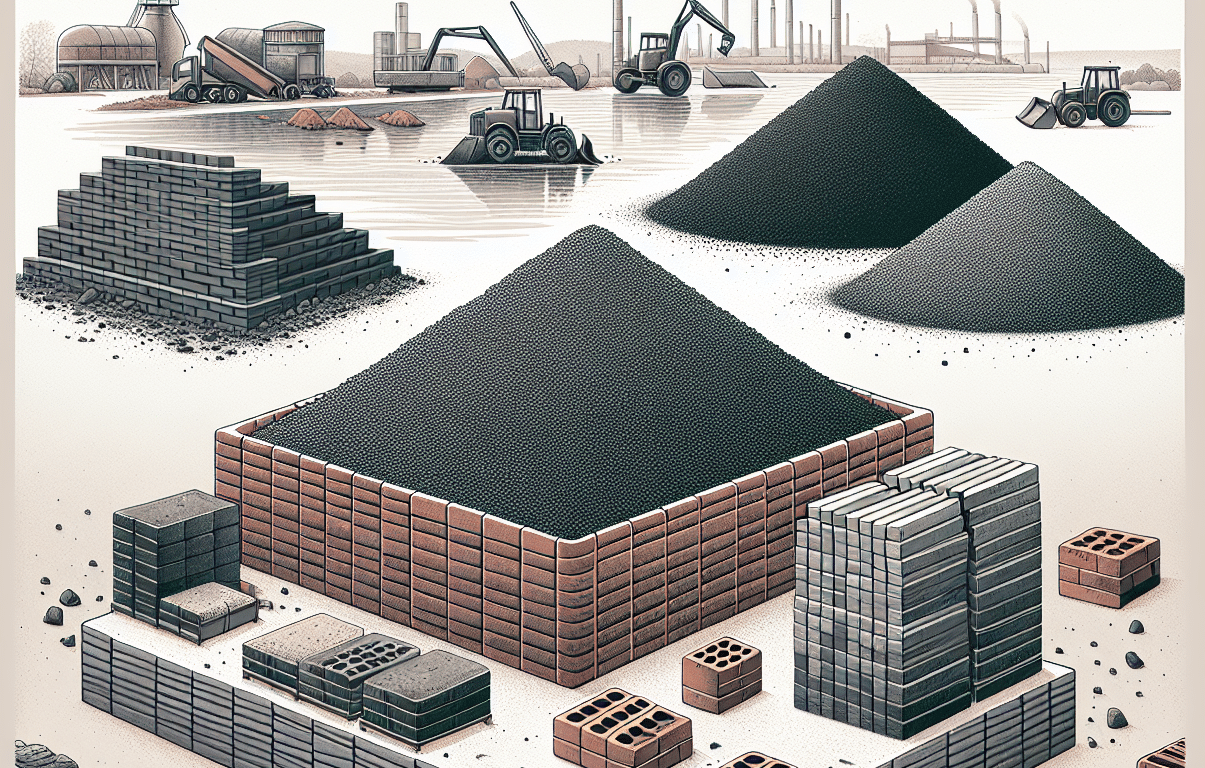

Inventory Management

The unsung hero of any deconstruction project is its inventory management system—meticulously cataloging and categorizing salvaged materials to ease their journey from past to future use.

Managing inventory isn’t just about keeping track of what’s been saved; it’s about creating opportunities for these materials to find new homes. By photographing materials before removal and utilizing platforms for tracking, we invite buyers to visualize the potential of these reclaimed treasures. This approach not only streamlines reuse and recycling efforts but also champions the cause of sustainable building practices.

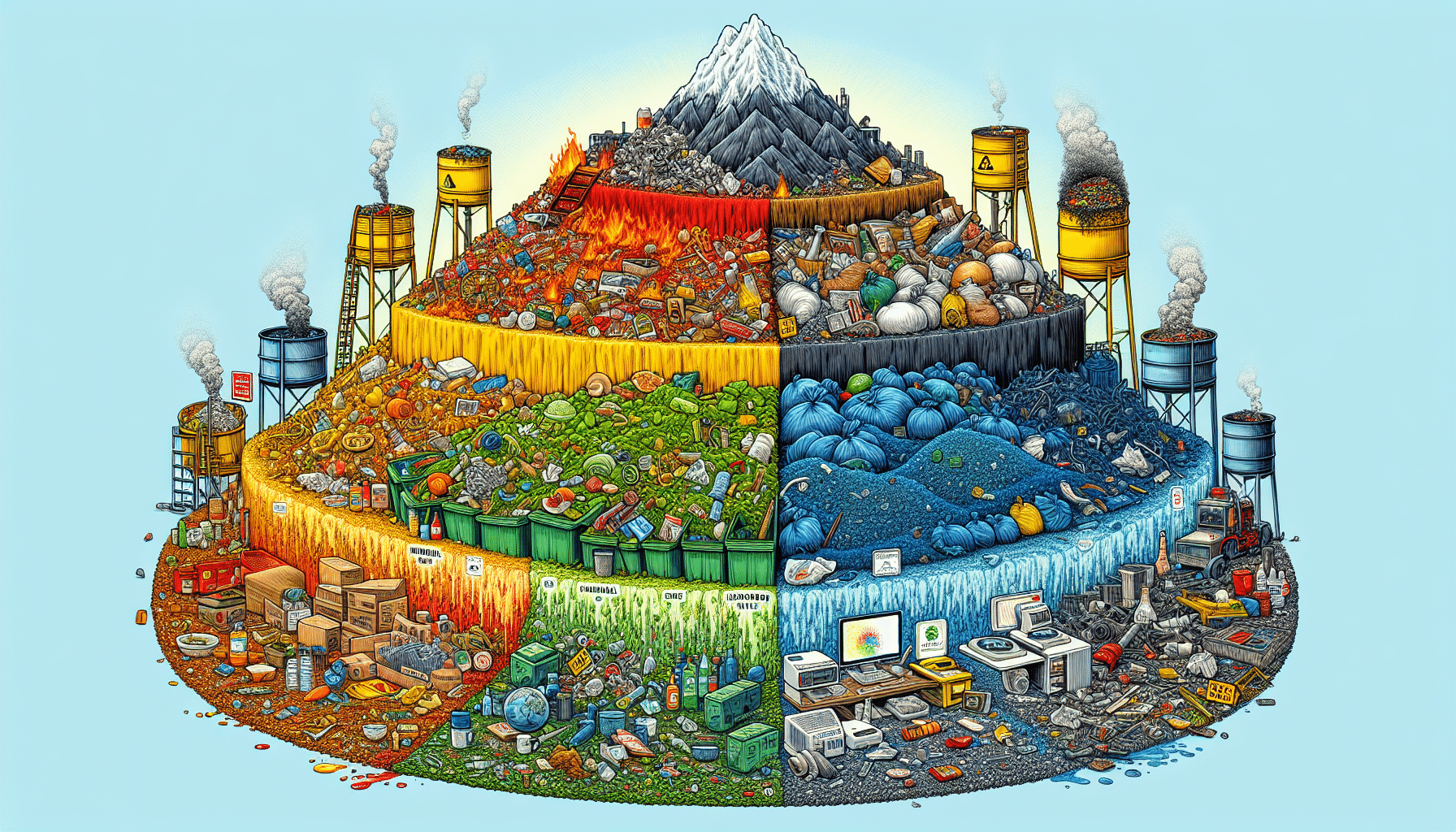

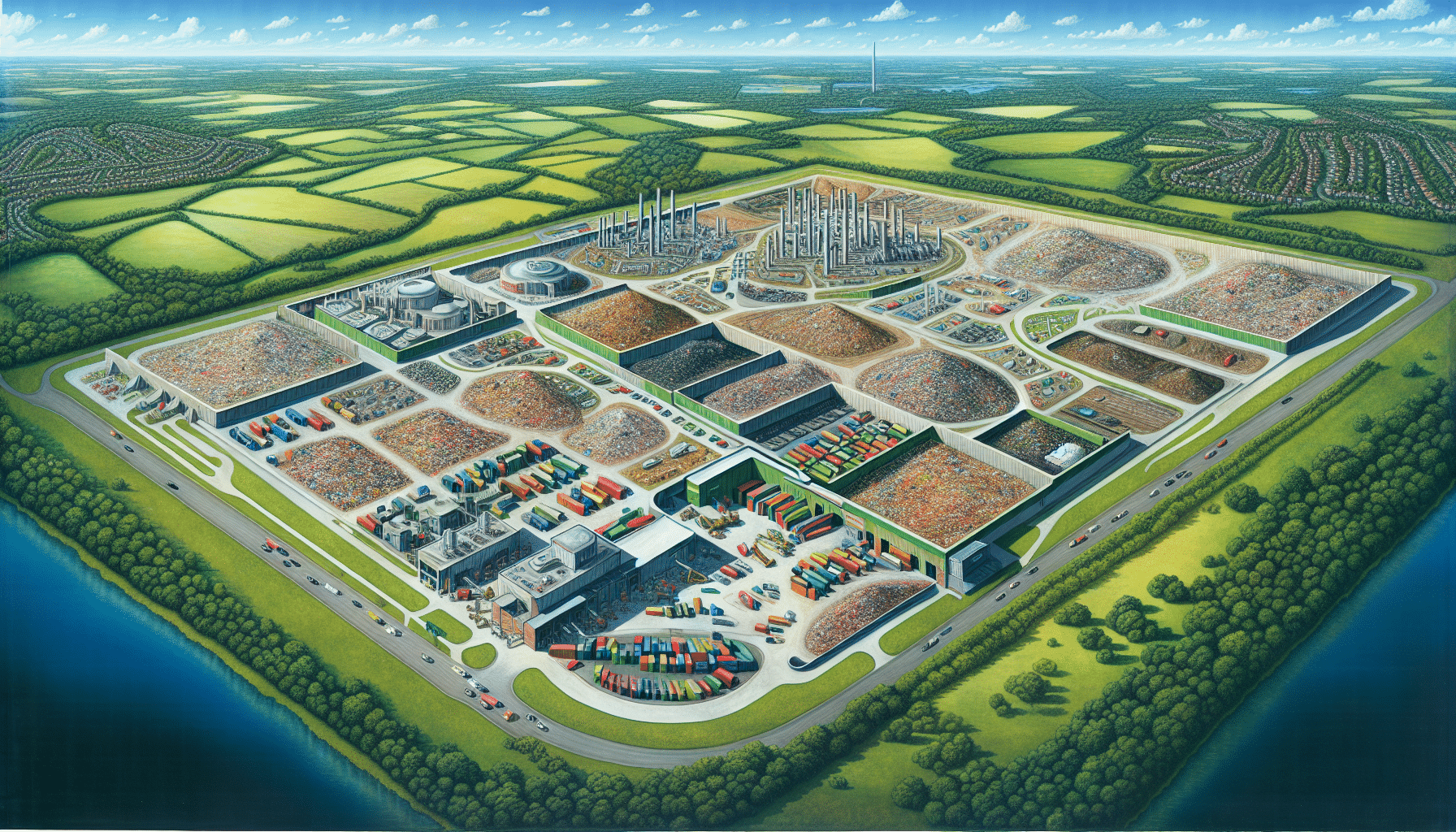

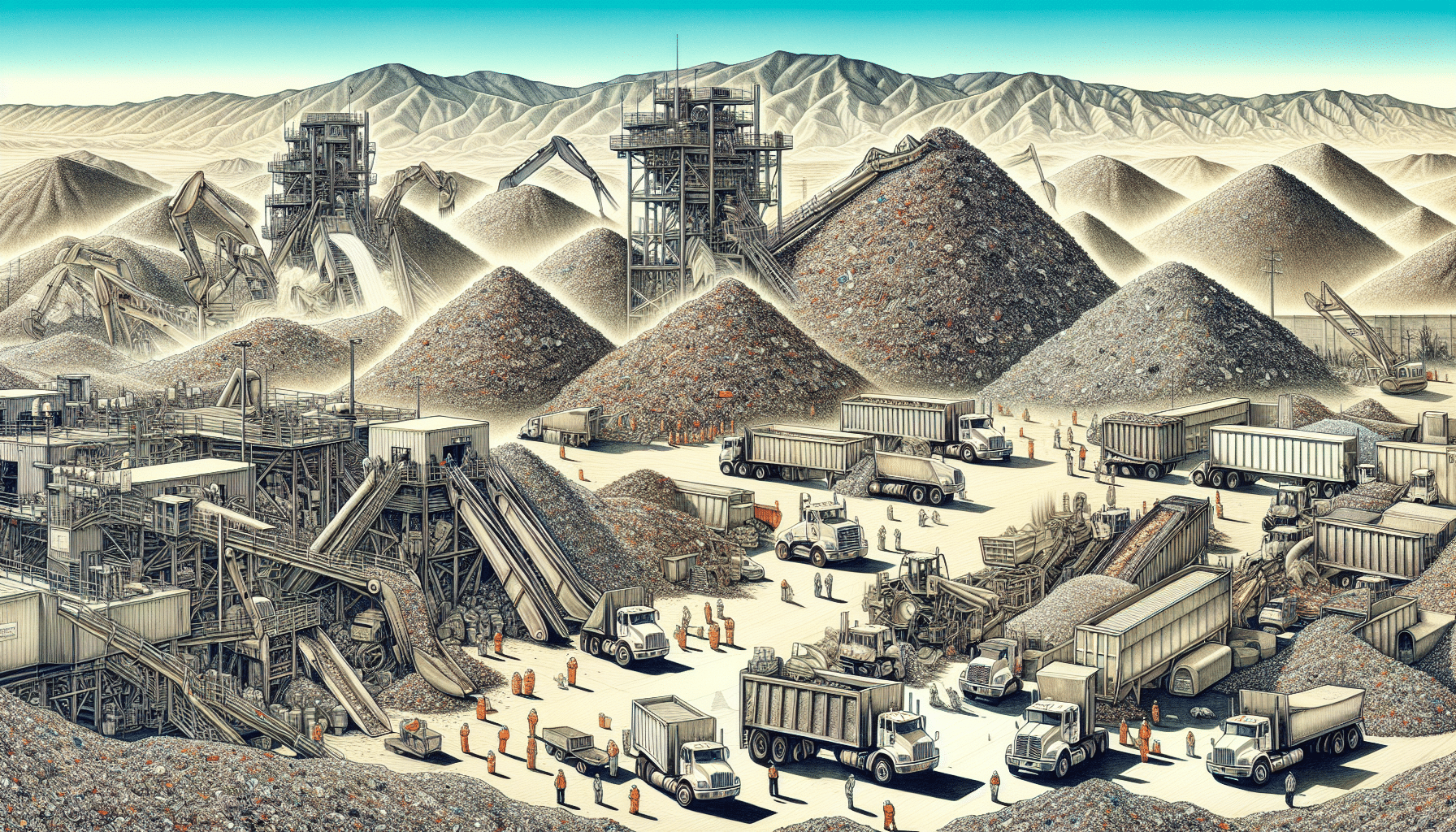

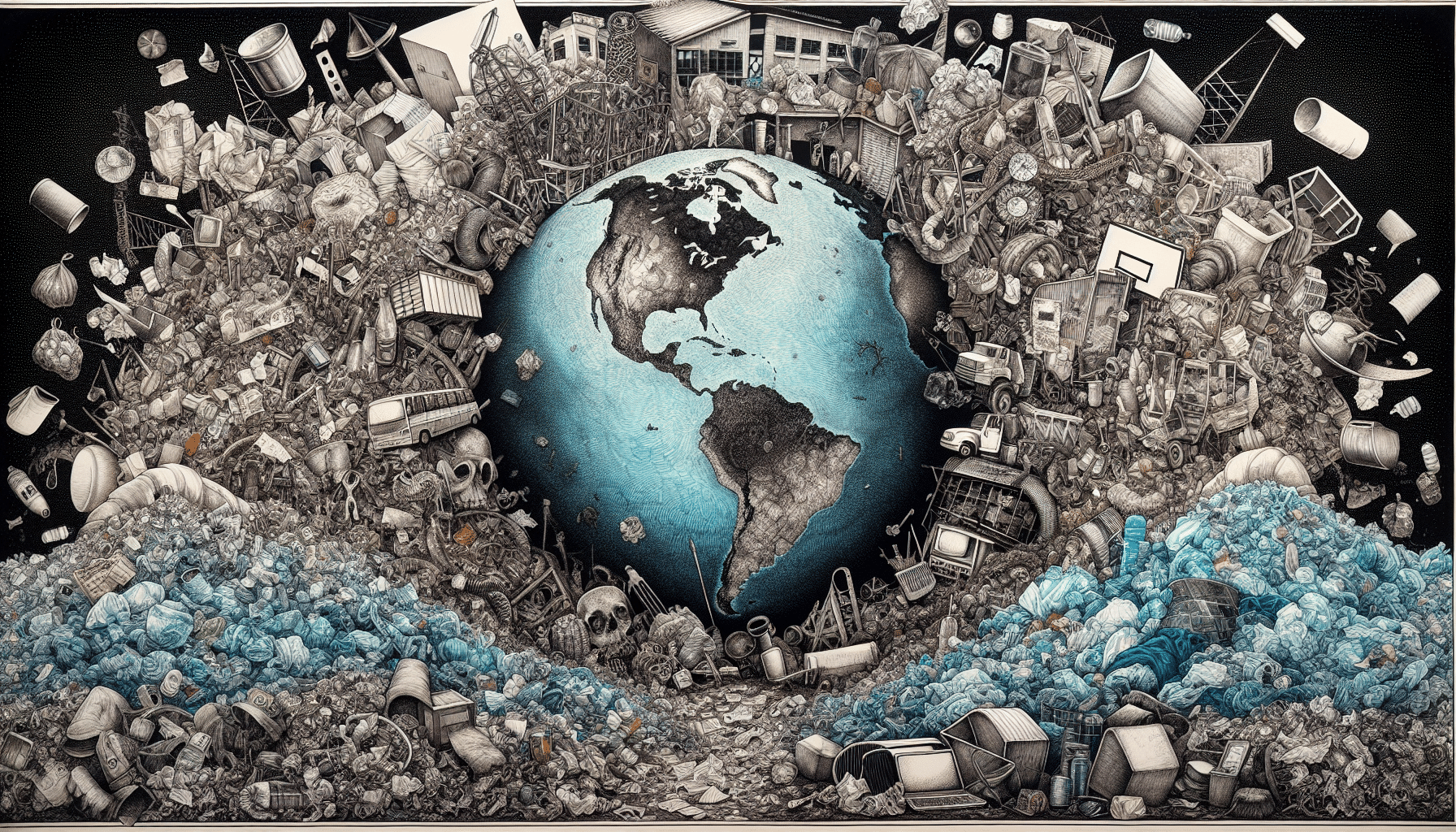

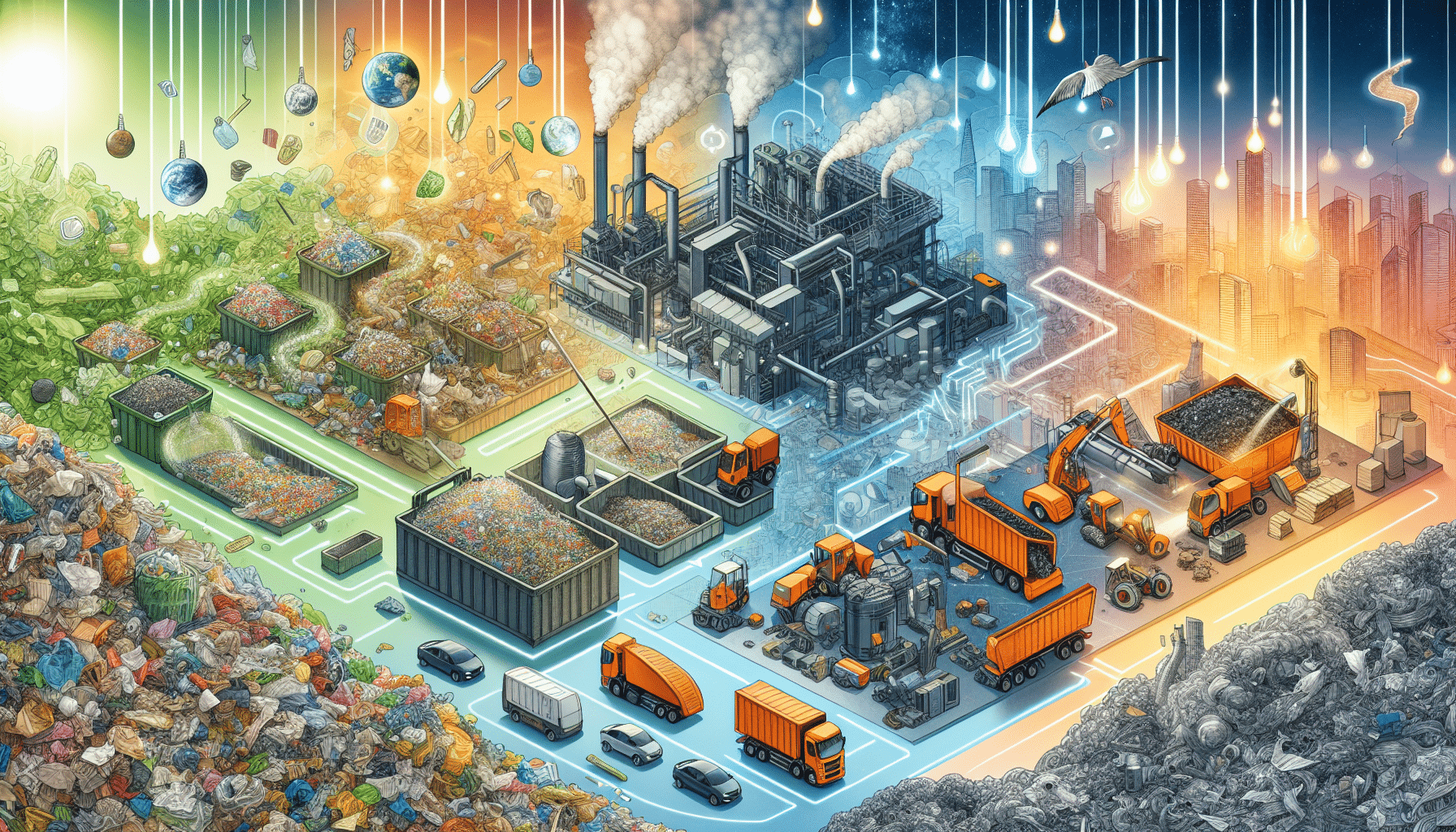

Environmental and Economic Impact

The ripple effects of deconstruction reach far beyond the immediate site. In an industry that consumes 40% of global energy and resources, the shift toward deconstruction is more than a trend; it’s a necessary evolution. By reclaiming materials and reducing landfill waste, we’re not just preserving resources but crafting a legacy of environmental stewardship and economic growth.

Reducing Greenhouse Gas Emissions

The battle against climate change finds an ally in deconstruction. By opting for material reuse over creating new materials, we significantly cut down on the carbon emissions tied to manufacturing and transportation, thus combating air pollution. It’s a meaningful stride towards cleaner air and a healthier planet.

Moreover, deconstruction spares our landfills from becoming the final resting place for decomposing materials that emit methane, a potent greenhouse gas. The resulting reduction in emissions is not just a statistic; it’s a testament to how our choices in building removal can contribute to a larger environmental cause.

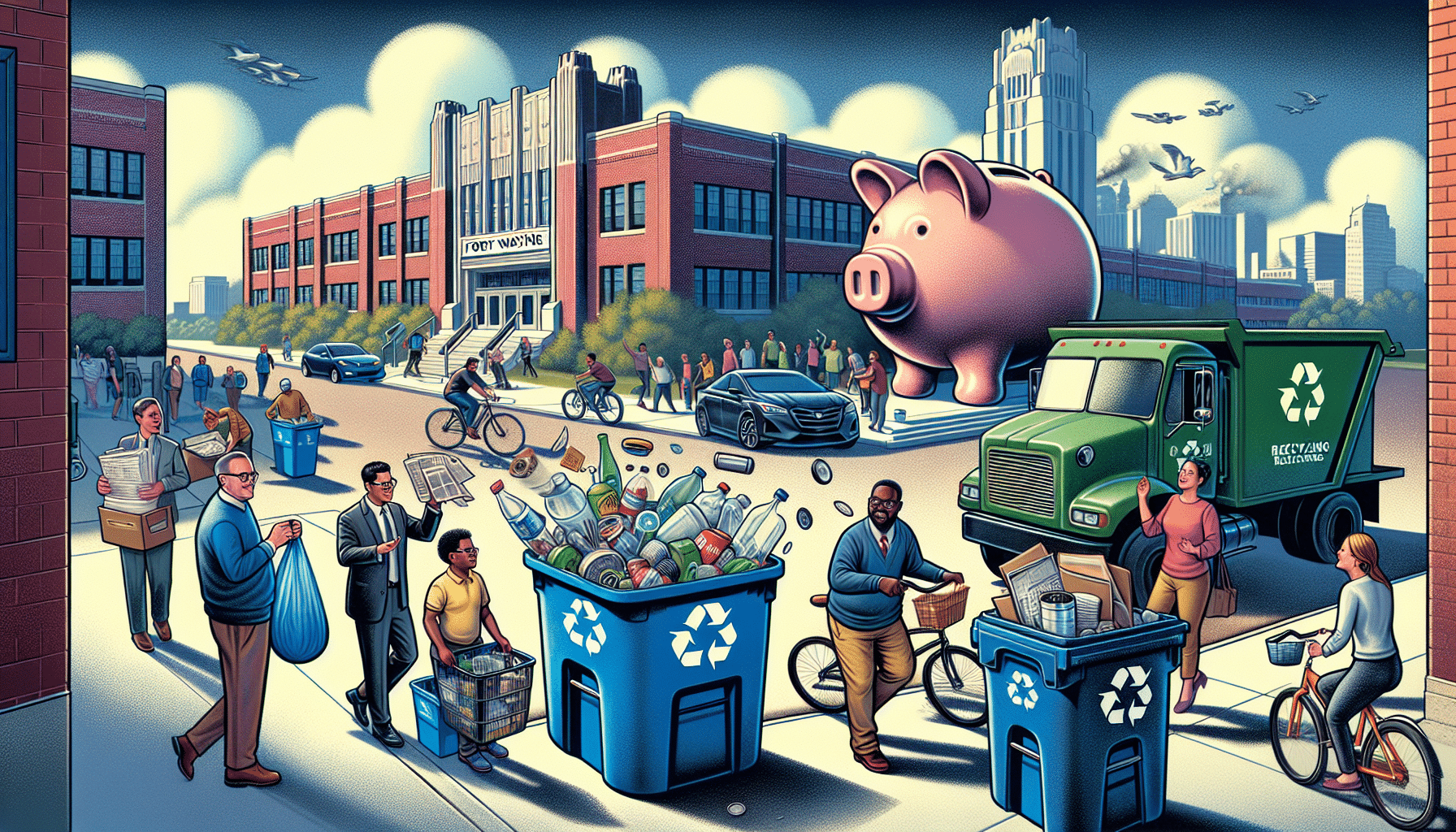

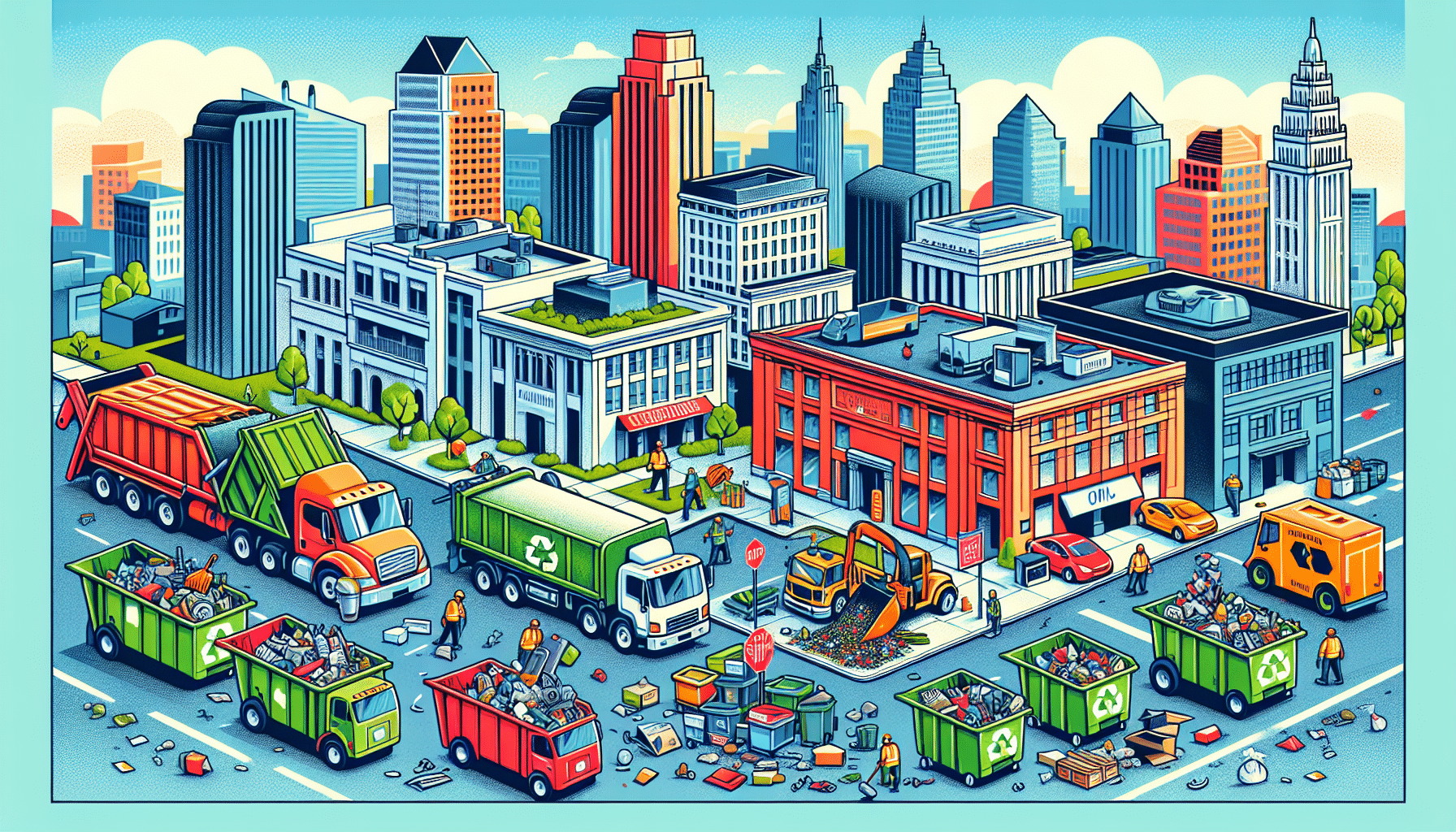

Economic Benefits

Deconstruction is a beacon of hope for local economies and the job market. Compared to demolition, it demands more hands-on work, translating into job creation and opportunities for skill development. This surge in employment extends beyond the deconstruction site to the realms of material warehousing, retail, and sales, invigorating the local economy.

The economic benefits are multifold; cost savings from reusing materials, reduced landfill fees, and the potential for tax-deductible donations all contribute to the financial allure of deconstruction. This, in turn, encourages businesses and communities to invest in a practice that supports the environment and their bottom line.

Practical Steps to Implement Deconstruction

Implementing deconstruction is not merely a technical endeavor but a collaborative one involving stakeholders across the spectrum—from urban planners to historic preservationists. To shift the industry’s gears towards sustainable building removal, we must establish clear strategies, nurture local markets, and incentivize the transition through policy reforms to shift the industry’s gears towards sustainable building removal.

Setting Goals and Targets

Embarking on a deconstruction project without clear goals is like navigating without a compass. Setting specific targets for waste reduction and material reuse provides direction and purpose, ensuring that every action aligns with the overarching mission of sustainability. We uphold accountability and foster continuous improvement by embedding these targets in city plans and monitoring progress, we uphold accountability and foster continuous improvement.

These benchmarks act as beacons, guiding us towards a future where the construction hierarchy is redefined and the adaptive reuse of such buildings is not just an option, but a priority. With each goal met, we inch closer to a built environment that respects its past and safeguards its future.

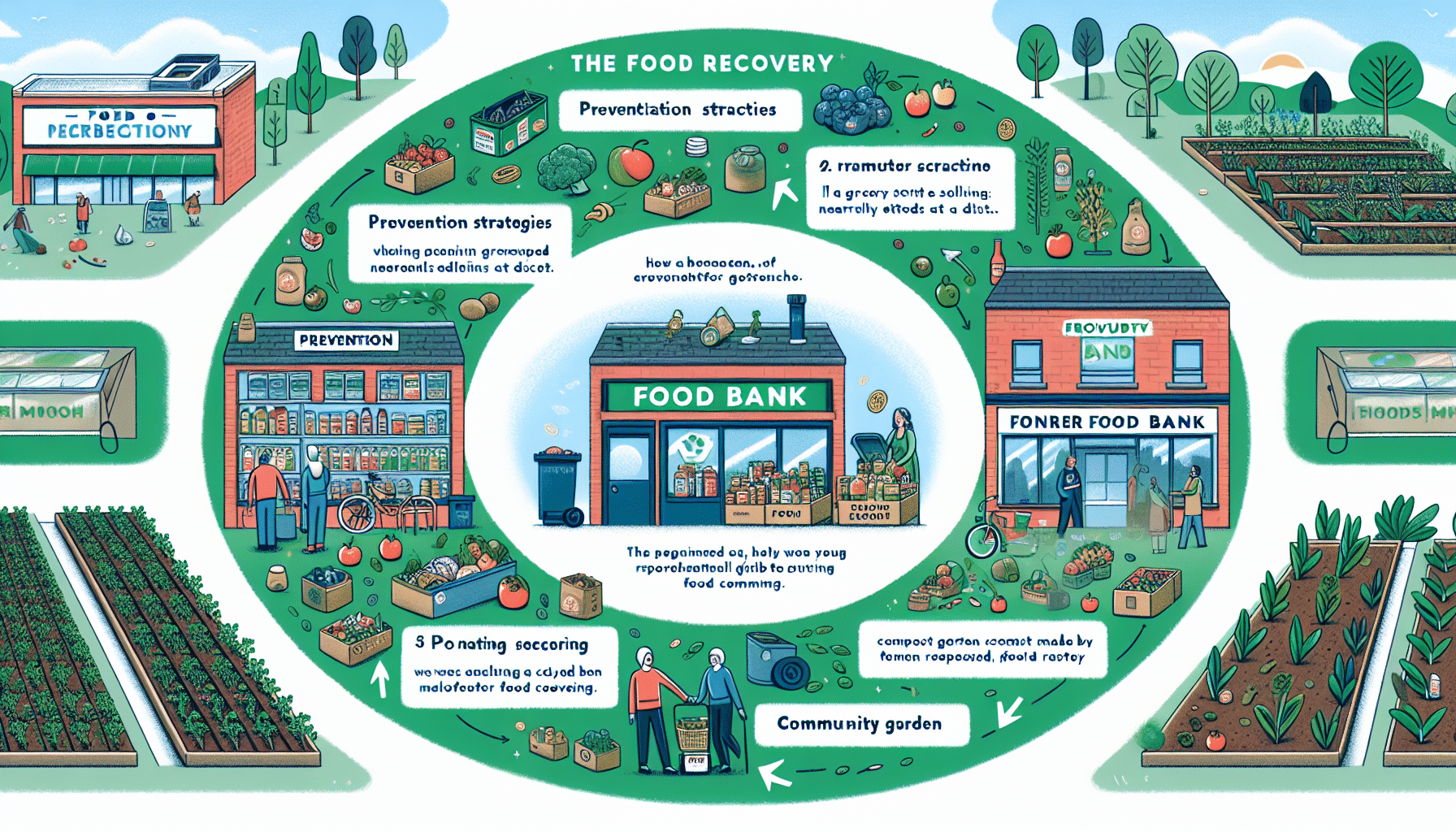

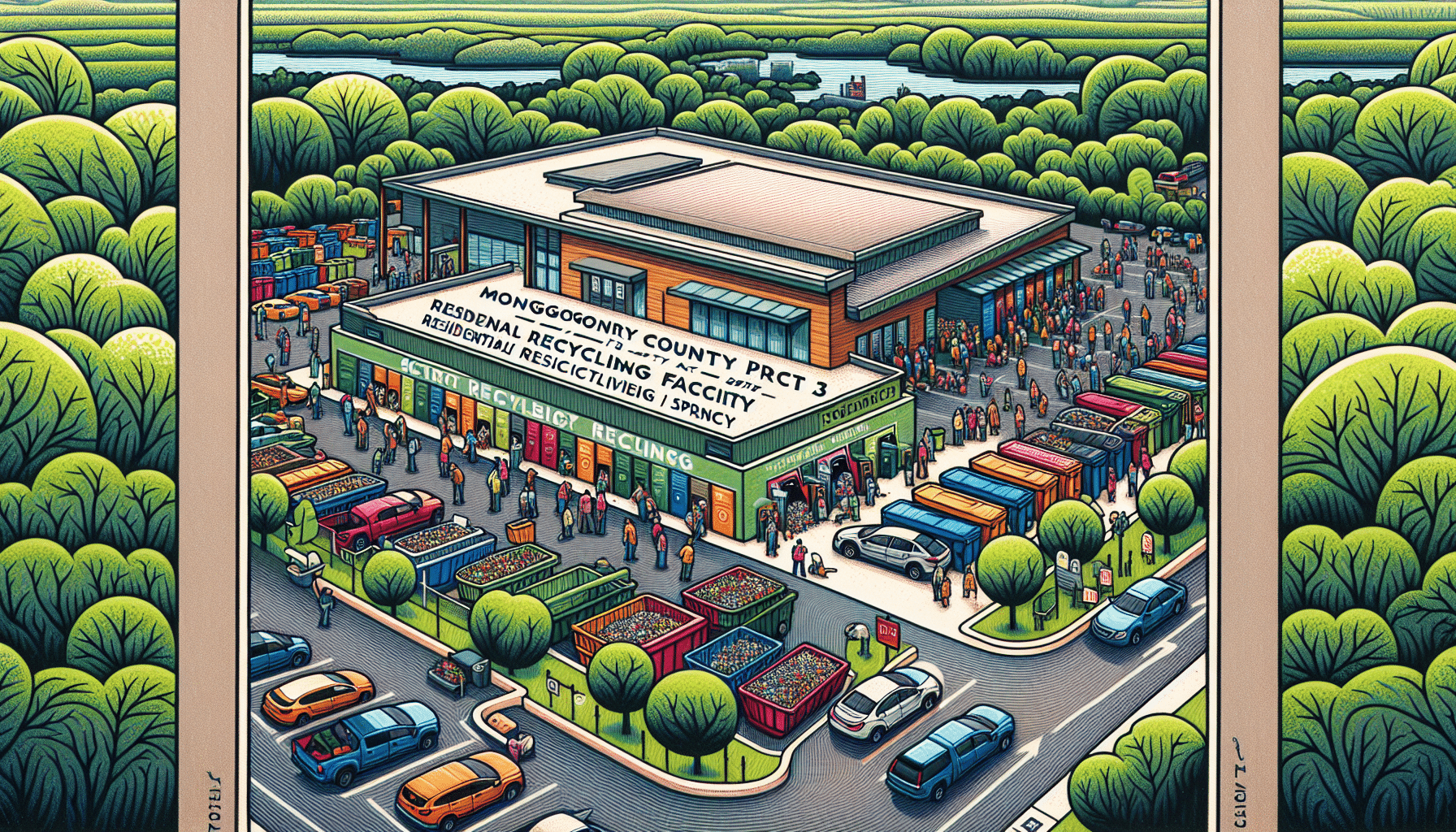

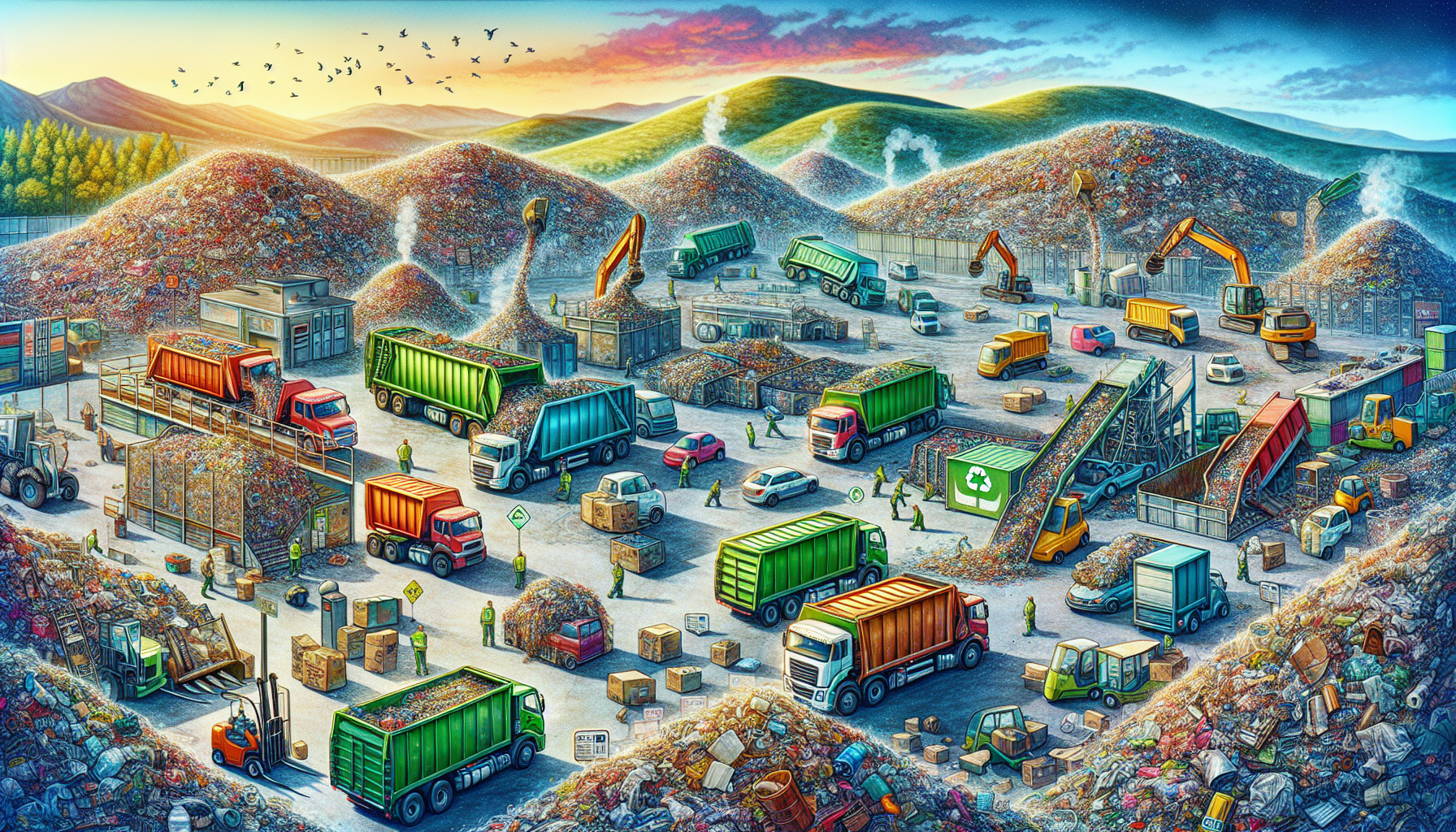

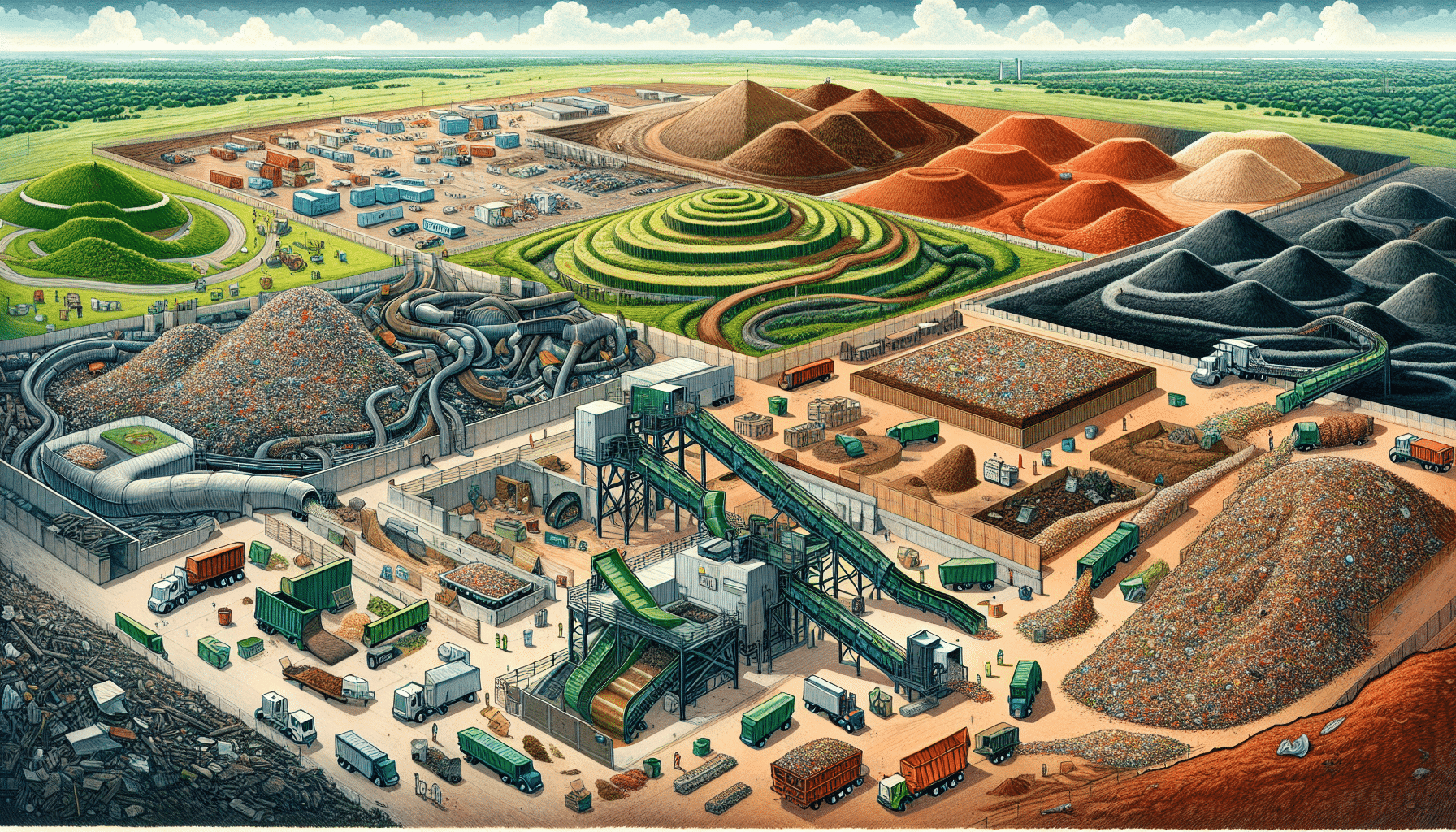

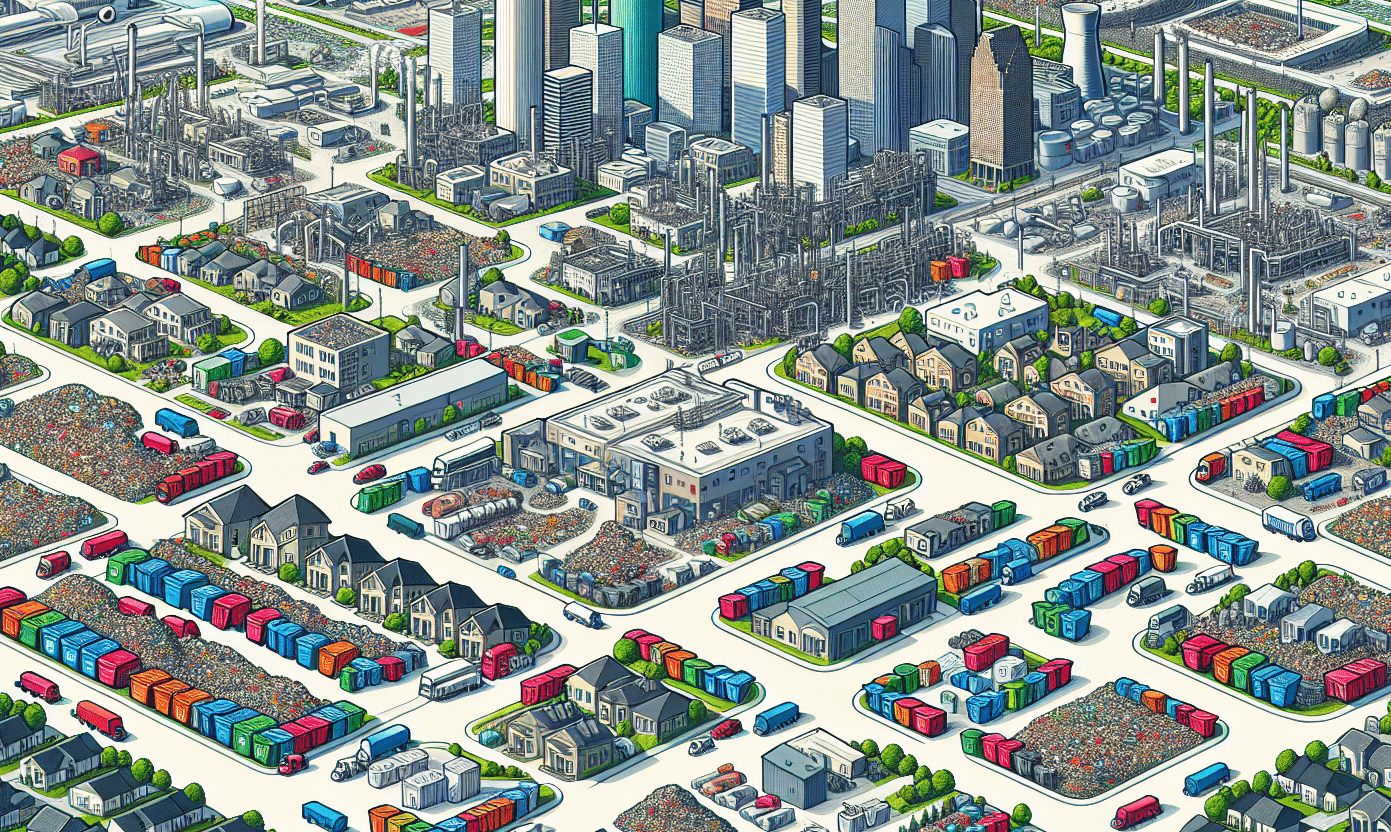

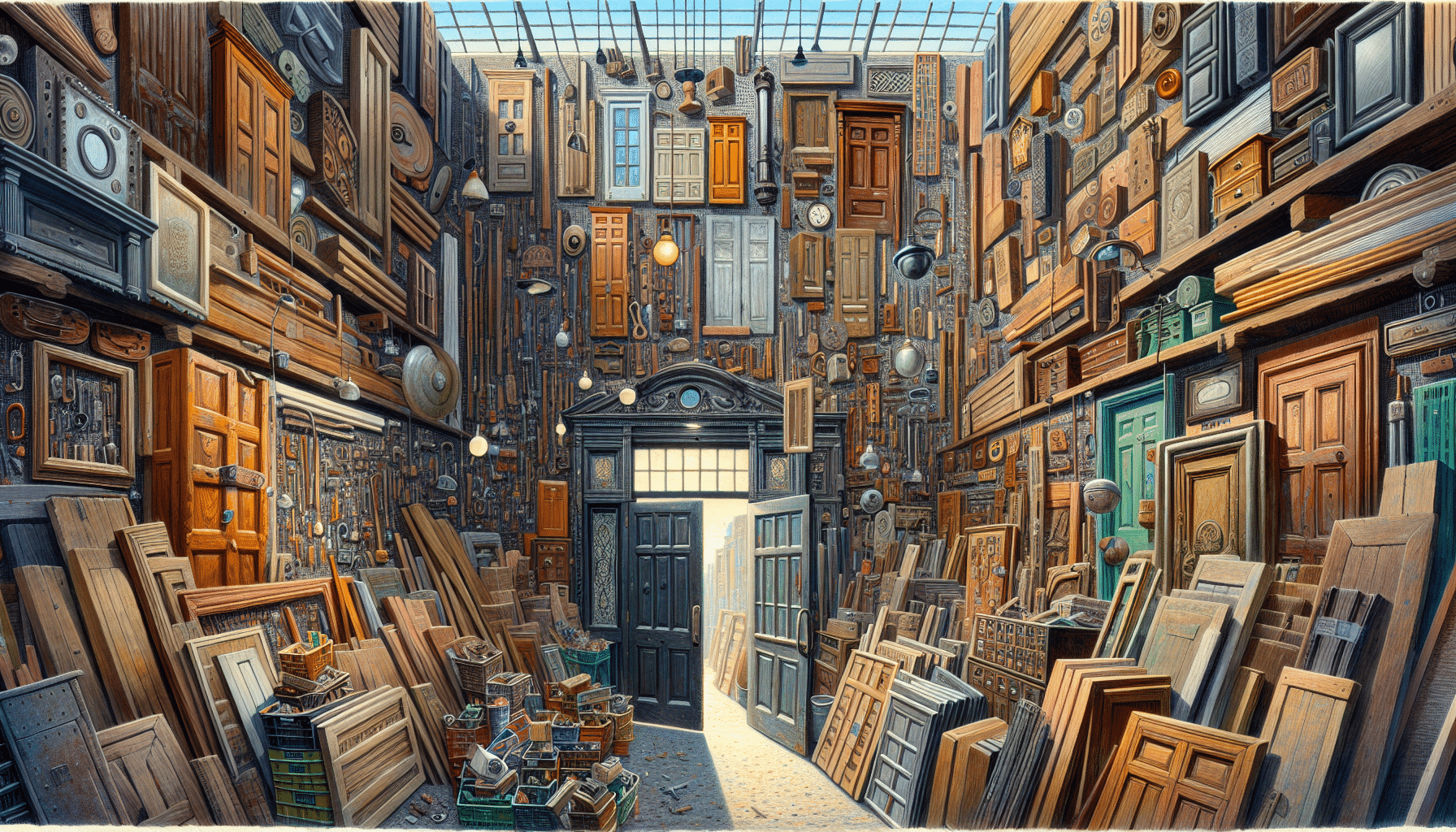

Developing Local Markets

The transformative power of deconstruction hinges on the strength of local markets. By establishing retail outlets for salvaged materials and promoting their adaptive reuse, we create a thriving ecosystem where these materials are available and sought after. Such markets support local self-reliance and foster a culture where sustainability is not just a buzzword but a common practice.

Partnerships with local businesses enable a circular economy where materials are continuously repurposed, reducing the need for virgin resources and empowering communities. These regional markets become the bedrock of a sustainable construction industry, one that values resource efficiency and environmental responsibility.

Policy and Incentives

To catalyze the adoption of deconstruction, policy, and incentives must align with the industry’s needs. Grants and permitting incentives can lower barriers to entry, making it financially feasible for businesses and non-profits to embrace waste reduction strategies. Expedited permitting processes and reduced costs can make deconstruction a more attractive proposition, leveling the playing field with traditional demolition.

Mandatory ordinances can further favor deconstruction, requiring it for certain buildings and promoting a systemic shift towards material reuse. Such policies are not just tools for change; they are the building blocks of a new era in the built environment, one where deconstruction is not the exception but the norm.

Overcoming Challenges in Deconstruction

The journey towards widespread deconstruction adoption is not without its hurdles. Recognizing and addressing challenges such as the time-intensive nature of the process, higher labor costs, and the management of hazardous materials is essential for the progress of this sustainable practice.

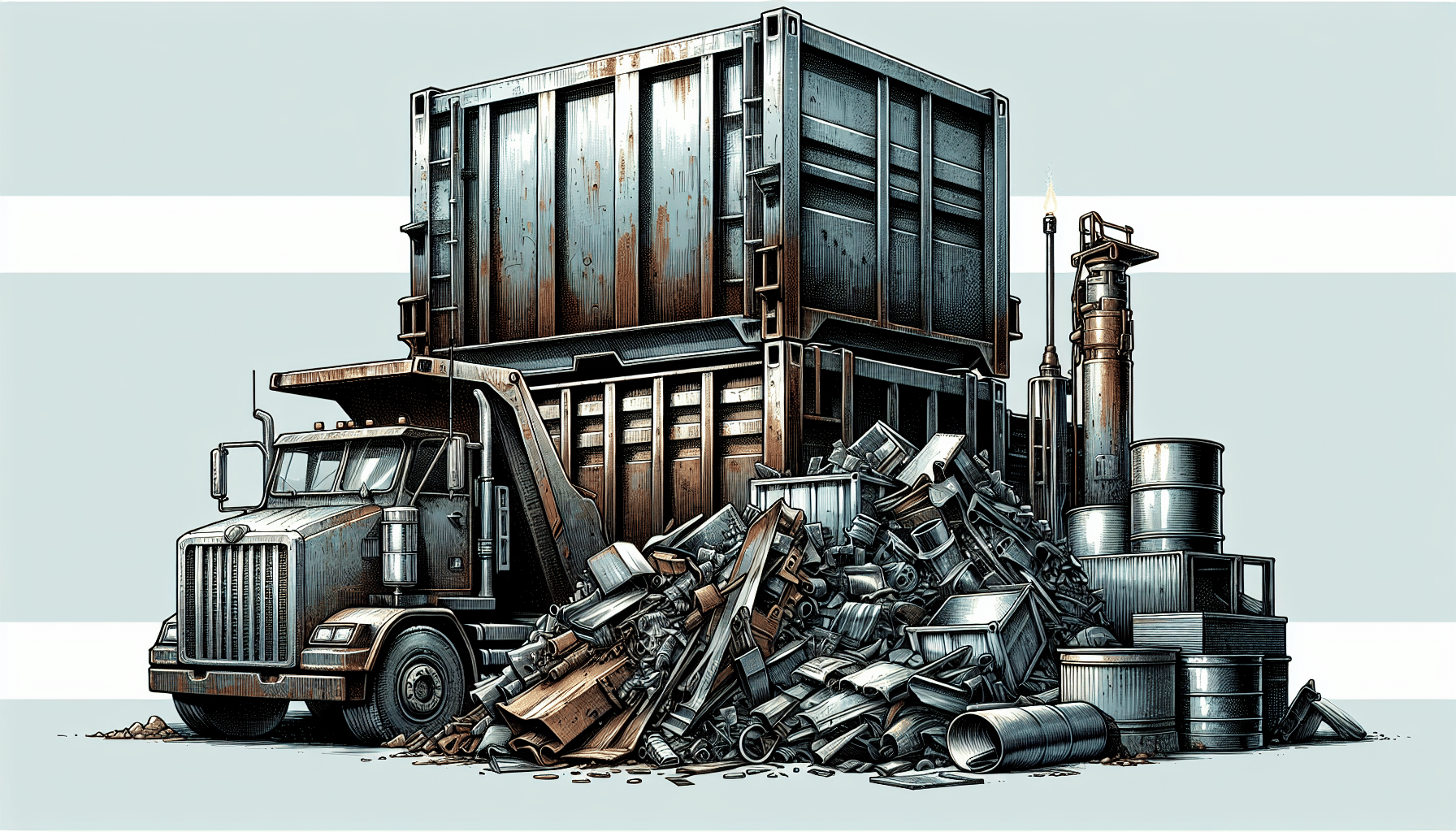

Higher Labor Costs

Deconstruction’s labor-intensive nature is both its strength and its challenge. Mechanical demolition might employ a handful of workers, but deconstruction requires a larger team to ensure the careful disassembly and preservation of materials. Yet, this increase in labor costs can be managed through workforce training, equipping workers with the skills necessary to execute deconstruction efficiently and safely.

Investing in training not only addresses the cost issue but also contributes to workforce development. By preparing workers for the unique demands of deconstruction, we empower them to play a pivotal role in this burgeoning sector, ultimately benefiting both individuals and the industry as a whole.

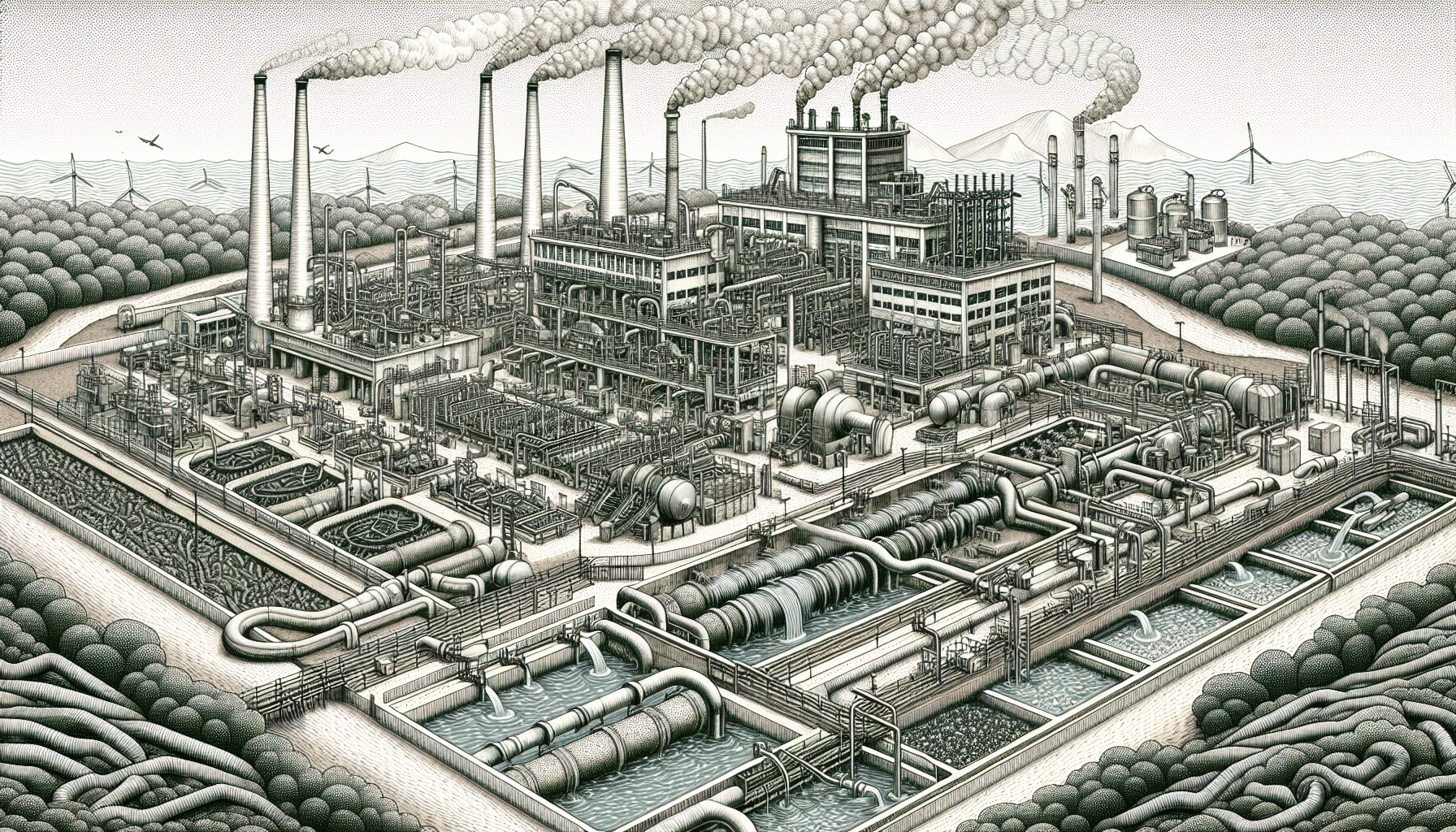

Handling Hazardous Materials

The specter of hazardous materials looms over many deconstruction projects, particularly those involving older buildings where substances like asbestos and lead were commonly used. A proactive approach, starting with an environmental assessment conducted by the Environmental Protection Agency, is crucial to identify and mitigate the risks associated with these materials.

Certified contractors, trained to handle such hazards, are integral to ensuring the safety of workers and the environment. Their expertise not only safeguards health but also reinforces the practice of deconstruction as a responsible and conscientious alternative to demolition.

Building Code Updates

Building codes are the blueprint for safe and sustainable construction. By updating these codes to explicitly allow the reuse of salvaged materials, we pave the way for their integration into new structures. This step is vital in normalizing the use of reclaimed materials, breaking down barriers to their adoption, and fostering a built environment that fully embraces the principles of deconstruction.

Collaboration with code officials can result in clear reuse guidelines, ensuring that salvaged materials contribute to the sustainability of new buildings while maintaining safety and performance standards. This proactive updating of building codes signals a commitment to resource conservation and innovation within the industry.

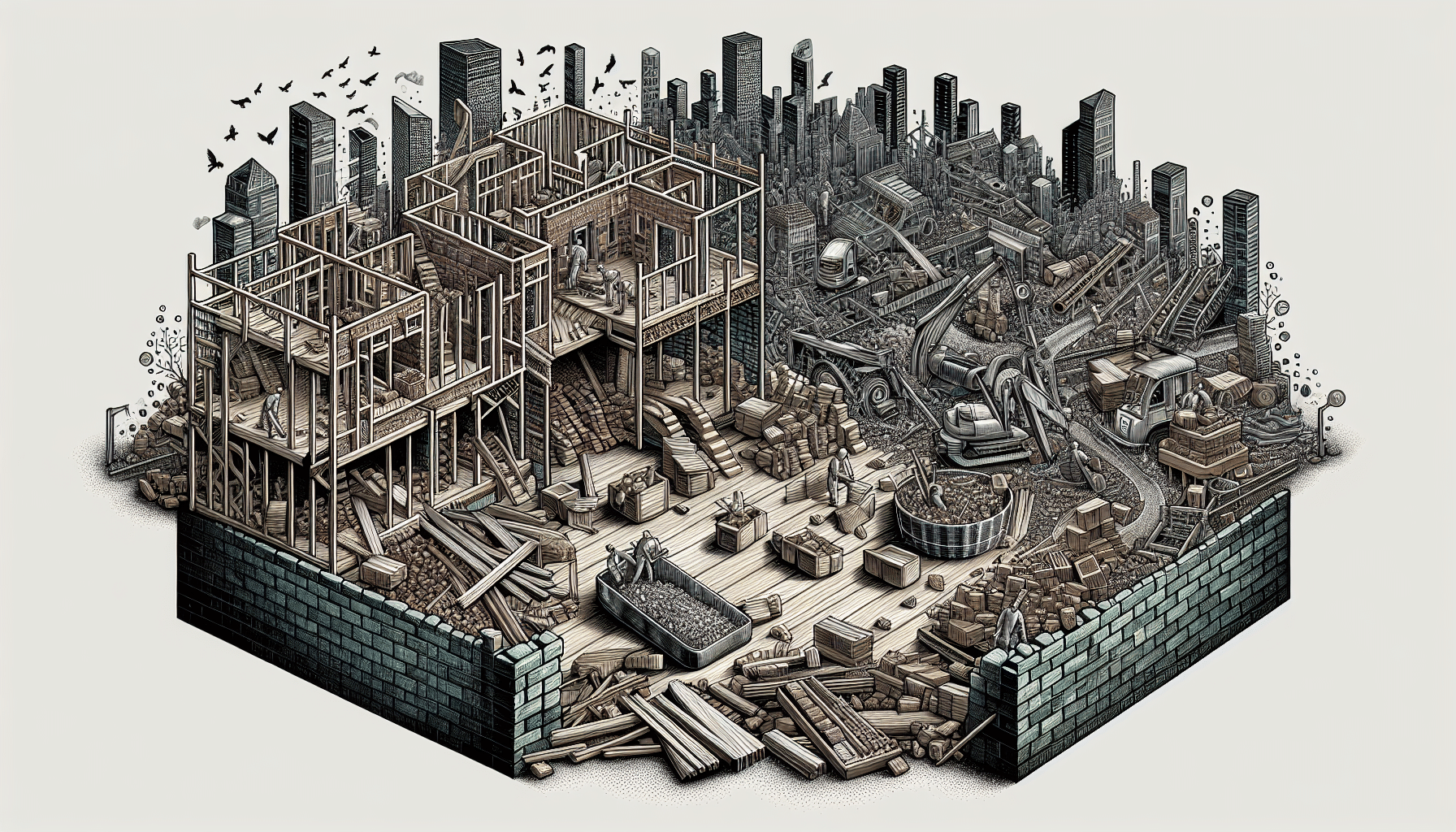

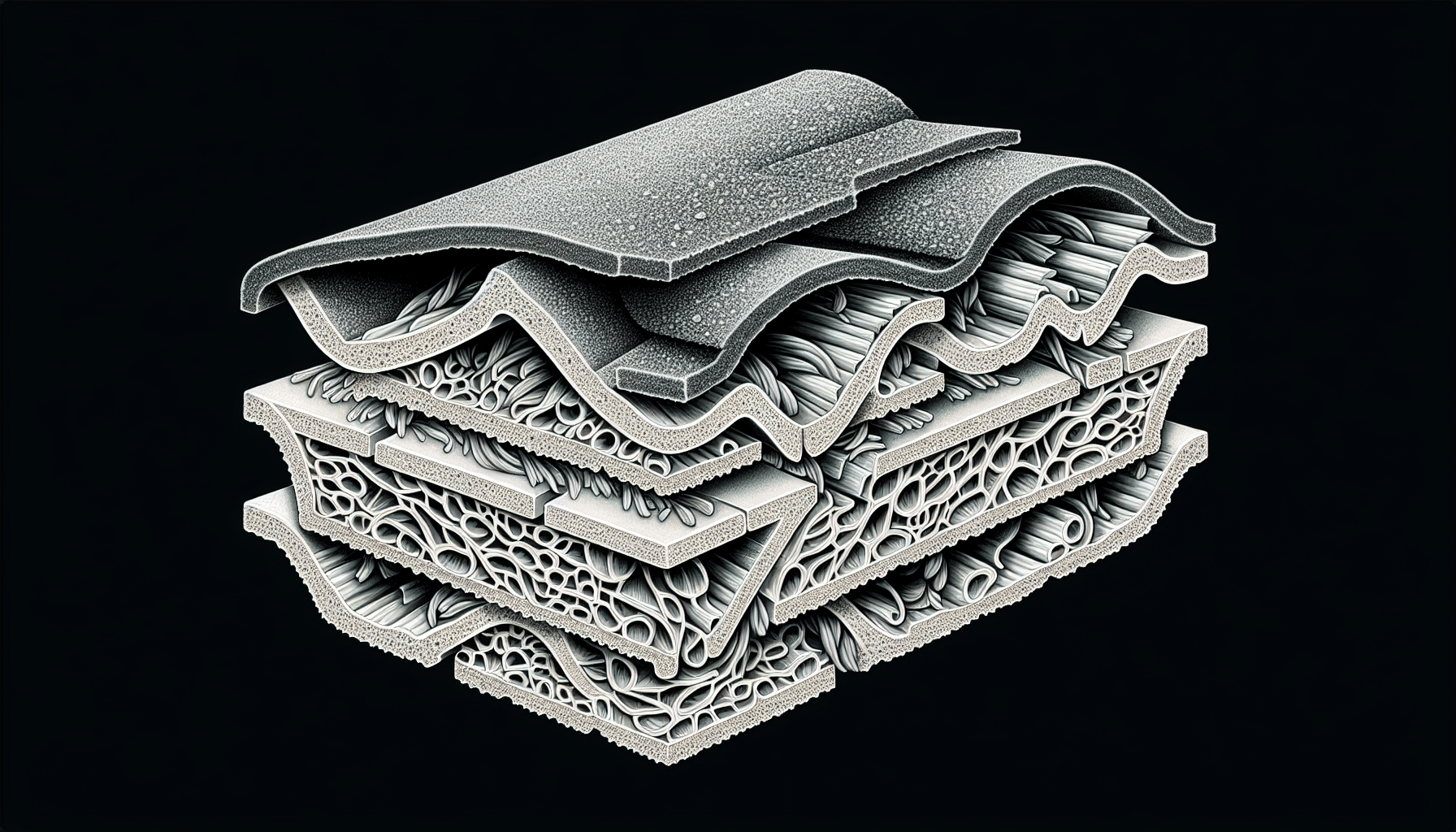

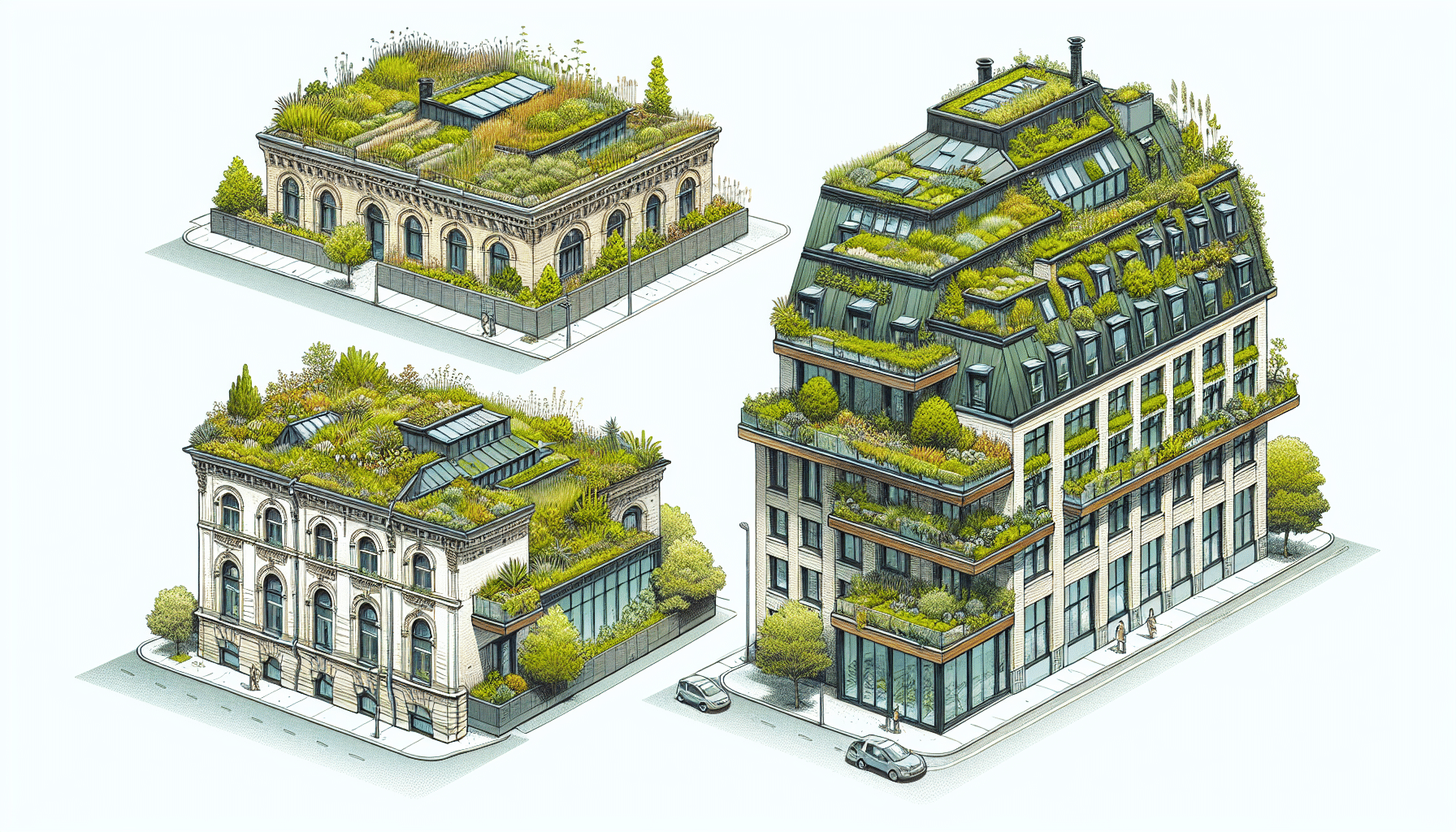

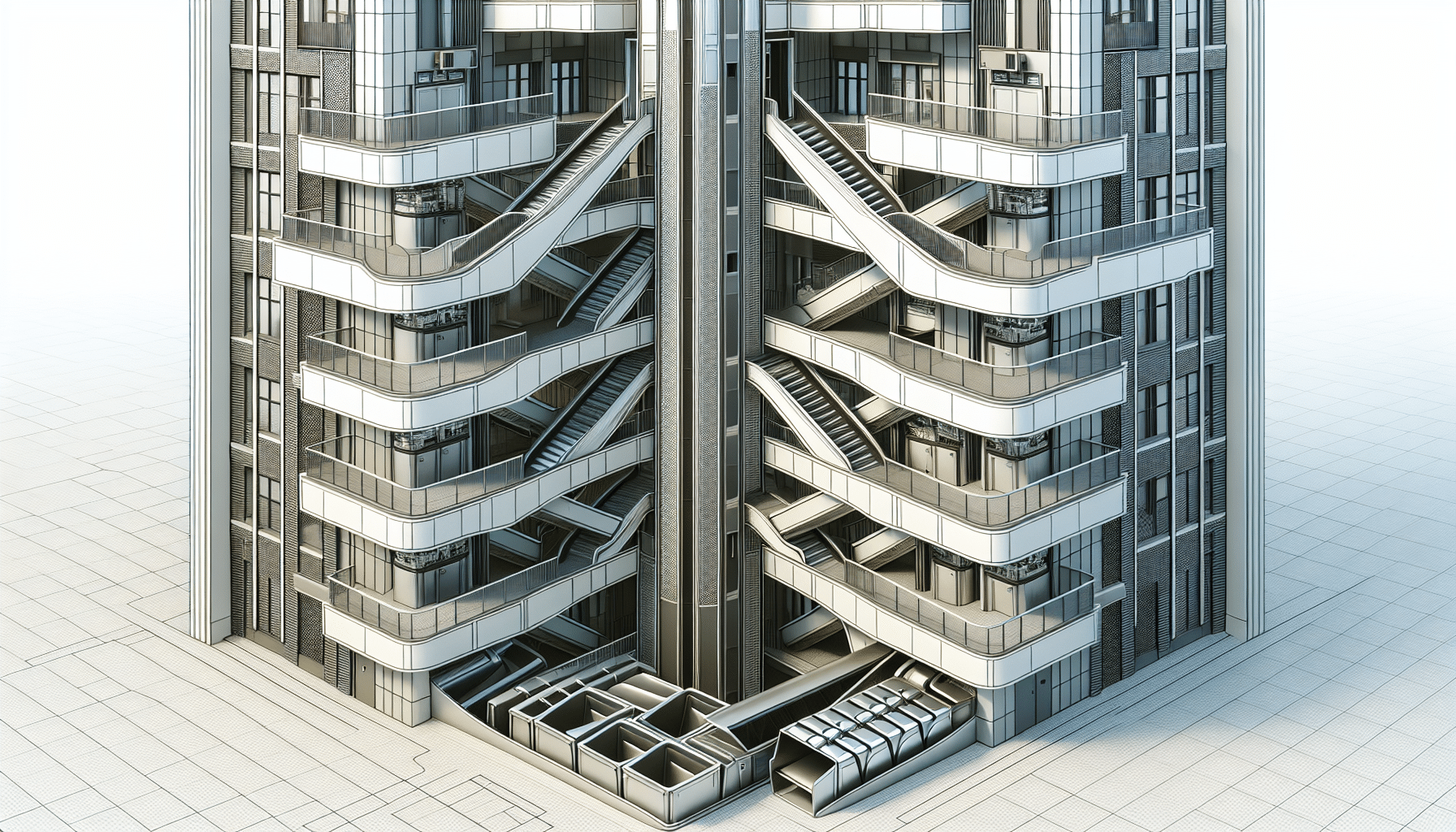

Designing for Future Deconstruction

As we embrace deconstruction, we must also look ahead, designing buildings with their eventual deconstruction in mind. The principles of Design for Deconstruction (DfD) principles encourage us to view buildings not as static entities but as dynamic ecosystems that can evolve and adapt over time. By planning for a building’s end of life at the outset, we ensure that its components can live on, fostering a cyclical approach to material use in the built environment.

Simple Construction Methods

The key to facilitating future deconstruction lies in the simplicity of construction methods. By employing standardized building components and embracing open floor plans, we minimize the complexity of disassembly, making it easier to reclaim and repurpose materials once a building has served its purpose. This approach not only eases future deconstruction efforts but also aligns with the growing trend of modularity in design.

Simple construction methods are not just about ease of deconstruction; they also promote flexibility and adaptability in the use of space. As such, they are becoming a common practice in forward-thinking construction projects, reflecting a broader shift towards a more sustainable and responsive built environment.

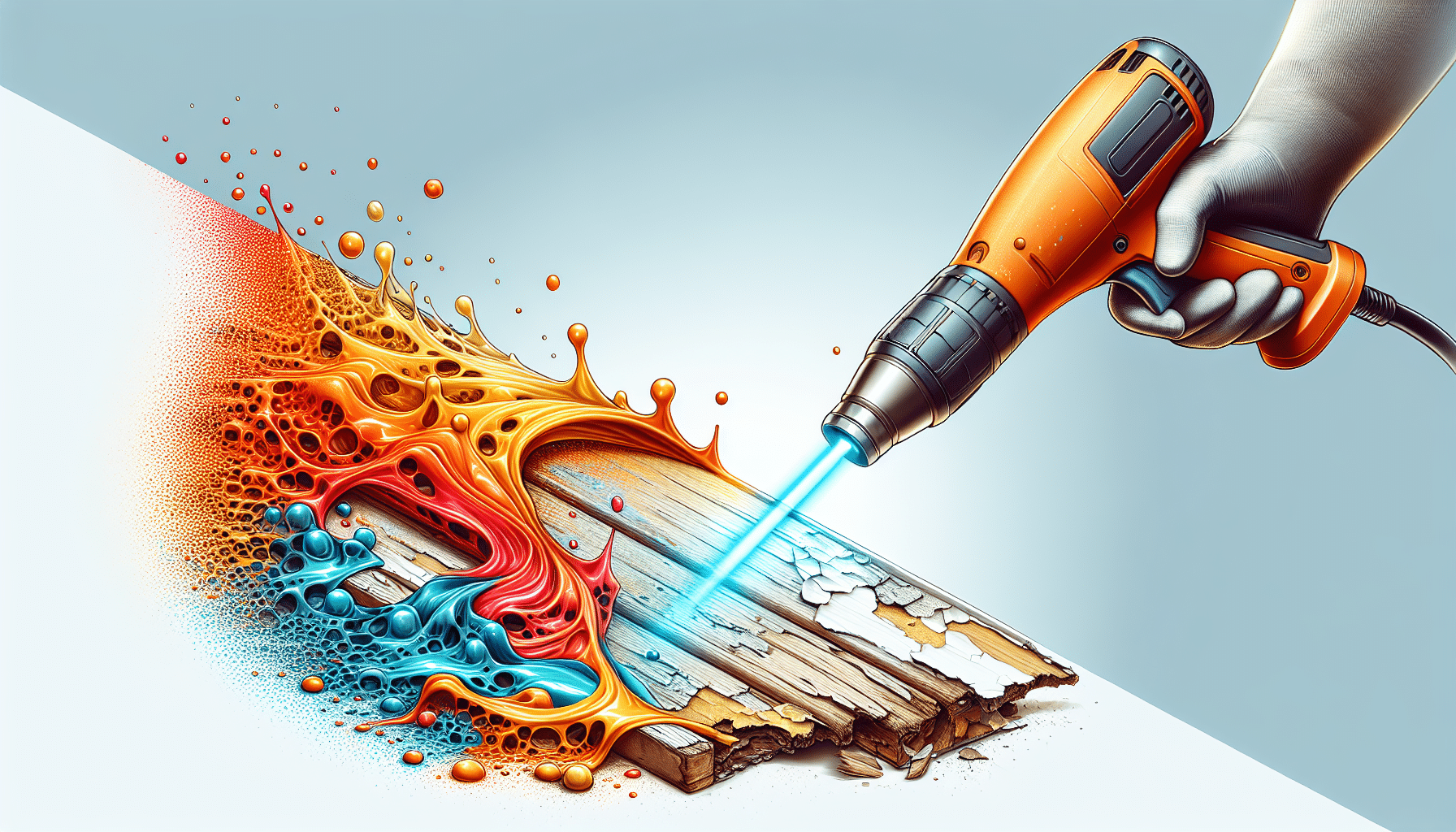

Use of Mechanical Fasteners

Beyond design, the choice of materials and methods for assembling building components greatly influences their potential for reuse. The use of mechanical fasteners, such as screws and bolts over adhesives, grants future deconstructors the ability to disassemble materials with minimal damage and maximum efficiency. This practice not only enhances the value of salvaged materials but also embodies the ethos of sustainable construction.

Incorporating mechanical fasteners into construction practices signals a commitment to the longevity and recyclability of building materials. It’s a strategy that anticipates change and prepares for it, laying the groundwork for buildings that can be easily adapted, upgraded, or deconstructed as the needs and values of society evolve.

Summary

In conclusion, mastering the art of deconstruction is not just about dismantling buildings; it’s about rethinking our relationship with the built environment. By favoring careful deconstruction over conventional demolition, we open the doors to a world where materials are cherished for their history and potential, where economic growth aligns with environmental sustainability, and where the design of new structures takes the future into account. May this exploration of deconstruction inspire you to consider the lasting impact of our buildings and the legacy we leave behind for generations to come.

Frequently Asked Questions

What differentiates deconstruction from conventional demolition?

Deconstruction involves carefully dismantling buildings to salvage materials for reuse, while conventional demolition simply tears down structures without regard for material recovery. This makes deconstruction a more sustainable and environmentally friendly option.

Are there economic benefits to choosing deconstruction over demolition?

Yes, choosing deconstruction over demolition can lead to economic benefits such as creating job opportunities, reducing disposal costs, and generating income by selling salvaged materials. Additionally, tax-deductible donations of reclaimed materials can help offset the higher labor costs.

How does deconstruction contribute to environmental sustainability?

Deconstruction contributes to environmental sustainability by minimizing waste, reducing the demand for new materials, and preventing the release of methane from decomposing materials. It salvages materials that would otherwise end up in landfills, ultimately reducing carbon emissions.

What are the key components of a successful deconstruction project?

Thorough planning, certified deconstruction contractors, and effective inventory management are key components of a successful deconstruction project. These elements maximize material recovery and facilitate reuse or recycling.

Can buildings be designed with deconstruction in mind, and if so, how?

Yes, buildings can be designed for deconstruction by using simple construction methods, standardized components, open floor plans, and mechanical fasteners instead of adhesives, which facilitates future disassembly and material reuse.